5-Axis CNC Machining ntawm Micro-Optic Cheebtsam nrog Sub-Micron Tolerances

Xav txog lub koob yees duab lens rau qhov chaw tshaj tawm txoj moo zoo lossis laser tivthaiv rau cov khoom siv kho mob. Yog tias cov khoom no sib txawv los ntawm micron, kev ua haujlwm tsis zoo. Qhov ntawd yog qhov twg5-axis CNC machiningci. Tsis zoo li cov qauv txheej txheem, peb cov thev naus laus zis siv cov khoom siv micro-optic-zoo li aspherical lo ntsiab muag thiab qhov chaw dawb-nrogsub-micron tolerances(raws li nruj raws li ± 0.1 µm). Rau kev lag luam uas xav tau kev ua tiav zoo (aerospace, kho mob, tiv thaiv), qhov kev txiav txim siab no tsis yog xaiv tau - nws yog lub luag haujlwm tseem ceeb.

Koj Qhov Kev Sib Tw Edge: Advanced Technology & Expertise

1.Cov cuab yeej txiav ntug

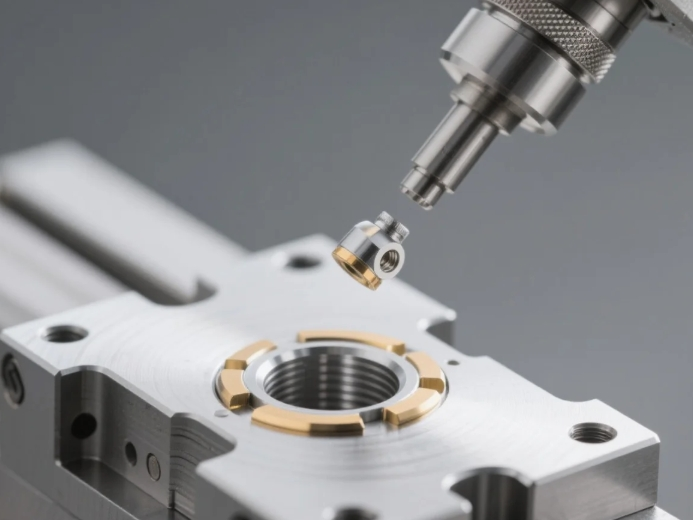

Peb xa tawmUltra-precision 5-axis CNC millsnruab nrog pob zeb diamond-txiav cov cuab yeej. Cov tshuab no txav ib txhij hla tsib axes, ua kom cov geometry nyuaj tsis tuaj yeem ncav cuag los ntawm 3-axis systems. Qhov tshwm sim? Flawless nto finishes nyob rau hauv0.1 µm Rathiab qhov tseeb qhov tseeb mus rau sub-micron qib.

2.Kev Txawj Ntse

Precision tsis yog hais txog cov tshuab-nws yog hais txog kev txawj. Peb pab neeg ua ke:

• Tool-tip radius tswjkom txo qis waviness

• Real-time tool them nyiajrau thermal / mechanical drift

Tsis muaj vibration machiningkom muaj kev ncaj ncees thaum txiav

Qhov kev txawj ntse no cia peb tuav cov ntaub ntawv los ntawm titanium rau optical-qib plastics (PEEK, UHMW) yam tsis muaj kev cuam tshuam qhov tseeb

3.Rigorous Quality Control

Txhua yam khoom tau dhau los ua ntau theem validation:

• Nyob rau hauv cov txheej txheem metrologysiv sub-micron optical ntsuas tshuab

• ISO 2768 Tus Qauv Zooua raws li kev kam rau siab

• 3D CAD deviation tsom xamlos xyuas kom meej ± 10% linewidth kam rau ua ntawm cov yam ntxwv tseem ceeb

Peb lub hom phiaj? Zero defects, txhua lub sijhawm.

Versatility Meets Innovation: Peb Ua Dab Tsi

Los ntawm prototypes rau high-volume ntau lawm, peb tshwj xeeb hauv:

• Micro-optics: Lub koob yees duab lo ntsiab muag, laser collimators, fiber-optic connectors

• Kev cai geometry: Freeform nto, microlens arrays, diffractive ntsiab

• Kev lag luam-kev daws teeb meem: Aerospace sensors, kho mob imaging devices, tiv thaiv optics

Nrog5-axis yooj, peb hloov kho rau koj tus qauv tsim - txawm li cas los xij.

Tshaj Tawm Tshaj Tawm: Kev Sib Koom Tes-Driven Support

Peb tsis yog cov khoom thauj khoom xwb; peb tsim kev sib raug zoo. Pebkev pabcuamsuav nrog:

• Design-for-manufacturability (DFM) tawm tswv yimkom optimize cov nqi / kam rau ua

• Expedited prototyping(sai li 72 teev)

• Kev pab txhawb nqa lub neejrau kev kho / kho dua tshiab

Koj txoj kev vam meej yog peb qhov kev ntsuas.

Vim li cas thiaj xaiv peb?

"Nrog 5-axis machining, peb tsim tag nrho tsib sab ntawm ib feem yam tsis rov kho dua - tshem tawm qhov yuam kev thiab ua kom lub sijhawm ua kom nrawm dua."

- Tom Ferrara, Tus Kws Tshaj Lij Tsim Khoom

Peb ua kekev siv technology tshiab,uncompromising zoo, thiabneeg-centric agility. Txawm hais tias koj xav tau 10 units lossis 10,000, peb xa qhov tseeb uas ua tau zoo.

Q: Dab tsi'koj lub lag luam twg?

A: OEM Service. Peb qhov kev lag luam yog CNC tshuab dhos ua tiav, tig, stamping, thiab lwm yam.

Q. Yuav tiv tauj peb li cas?

A: Koj tuaj yeem xa cov lus nug ntawm peb cov khoom, nws yuav teb rau hauv 6 teev; Thiab koj tuaj yeem tiv tauj nrog peb ncaj qha los ntawm TM lossis WhatsApp, Skype raws li koj nyiam.

Q.Dab tsi kuv yuav tsum tau muab rau koj rau kev nug?

A: Yog tias koj muaj cov duab kos lossis cov qauv, pls xav tias dawb xa tuaj rau peb, thiab qhia rau peb koj cov kev xav tau tshwj xeeb xws li cov khoom siv, kev ua siab ntev, kev kho deg thiab tus nqi koj xav tau, ect.

Q.Dab tsi txog hnub xa khoom?

A: Hnub xa khoom yog li 10-15 hnub tom qab tau txais cov nyiaj them poob haujlwm.

Q.Dab tsi txog cov nqe lus them nqi?

A: Feem ntau EXW LOSSIS FOB Shenzhen 100% T / T ua ntej, thiab peb tuaj yeem sab laj rau koj qhov kev xav tau.