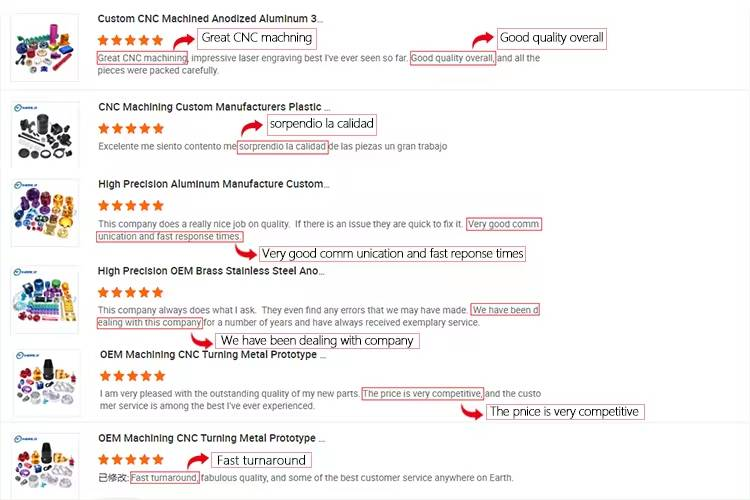

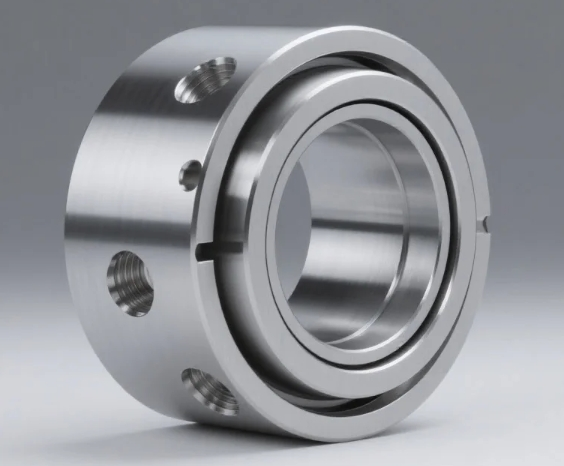

5-Axis Milled Titanium High-Load Bearing Cheebtsam rau Engineering Projects

Nyob rau hauv lub ntiaj teb xav tau ntawm engineering, qhov twg precision thiab durability yog tsis-negotiable,5-axis milled titanium cov khoomsawv ua tus txha nraub qaum ntawm cov ntawv thov siab. NtawmPFT, peb muab cov thev naus laus zis thev naus laus zis nrog ntau xyoo ntawm kev txawj ntse kom xa cov khoom uas rov txhais tau tias muaj kev ntseeg siab.

Vim li cas thiaj xaiv Titanium rau High-Load Applications?

Titanium qhov tshwj xeeb lub zog-rau-hnyav piv thiab corrosion kuj ua rau nws zoo tagnrho rau aerospace, kev kho mob cog, thiab kev siv tshuab. Txawm li cas los xij, machining no "xav hlau" yuav tsum muaj peev xwm ua tau zoo.

Peb5-axis CNC milling tshuab(xws li DMG Mori thiab Kern micromilling tshuab) ua kom cov geometries nyuaj nrog kev ua siab ntev li ± 0.005mm. Seb nws yog aerospace turbine blades los yog kho mob implant fittings, peb xyuas kom meej txhua contour raws nraim specifications.

Peb Qhov Zoo Tshaj Plaws

1.Advanced Manufacturing Ecosystem

●5-Axis Precision: Multi-axis kev sib hloov tshem tawm kev teeb tsa kev hloov pauv, txo qhov yuam kev thiab ua kom nrawm ntau lawm.

●Topology Optimization: Siv FEA simulations, peb ntxiv dag zog rau thaj chaw muaj kev ntxhov siab thaum txo cov khoom pov tseg - qhov tseem ceeb rau cov qauv hauv dav hlau .

2.Rigorous Quality Control

● Txhua batch tau txais kev sim metallurgical thiab CMM tshuaj xyuas kom lav ua raws li ASTM cov qauv.

● Kev saib xyuas lub sijhawm tiag tiag ntawm IoT-enabled machines ua kom muaj kev sib xws.

3.Xaus-rau-End Customization

● Los ntawm tus qauv 3D luam ntawv mus rau qhov tsawg-ntim CNC ntau lawm, peb txhawb cov haujlwm ntawm txhua qhov teev.

● Cov ntaub ntawv muaj ntau yam los ntawm Ti-6Al-4V rau Inconel, nrog rau kev xaiv rau kev kho deg zoo li anodizing.

4.Ntiaj teb no Service Network

24/7 kev txhawb nqa thiab 2-hnub hloov pauv rau kev txiav txim sai (piv txwv li, zirconia hybrid abutments) xyuas kom muaj sijhawm tsawg tsawg.

Daim ntawv thov thoob plaws kev lag luam

- Aerospace: Cav mounts, turbine hniav.

- Kho mob: Implants, phais cov cuab yeej.

- Automotive: Turbocharger Cheebtsam.

- Zog: High-torque connectors rau cua turbines.

Koj tus khub hauv Precision

NtawmPFTpeb tsis yog tshuab qhov chaw xwb-peb engineer kev daws teeb meem. PebISO 9001-certified chawthiabkev sib koom tes tswj qhov project(los ntawm CAD tsim mus rau kev soj ntsuam zaum kawg) xyuas kom koj lub zeem muag dhau los ua qhov tseeb.

Mus saib [https://www.pftworld.com/] txhawm rau tshawb nrhiav cov ntaub ntawv tshawb fawb lossis thov kev tsocai hnub no!

Q: Dab tsi'koj lub lag luam twg?

A: OEM Service. Peb qhov kev lag luam yog CNC tshuab dhos ua tiav, tig, stamping, thiab lwm yam.

Q. Yuav tiv tauj peb li cas?

A: Koj tuaj yeem xa cov lus nug ntawm peb cov khoom, nws yuav teb rau hauv 6 teev; Thiab koj tuaj yeem tiv tauj nrog peb ncaj qha los ntawm TM lossis WhatsApp, Skype raws li koj nyiam.

Q.Dab tsi kuv yuav tsum tau muab rau koj rau kev nug?

A: Yog tias koj muaj cov duab kos lossis cov qauv, pls xav tias dawb xa tuaj rau peb, thiab qhia rau peb koj cov kev xav tau tshwj xeeb xws li cov khoom siv, kev ua siab ntev, kev kho deg thiab tus nqi koj xav tau, ect.

Q.Dab tsi txog hnub xa khoom?

A: Hnub xa khoom yog li 10-15 hnub tom qab tau txais cov nyiaj them poob haujlwm.

Q.Dab tsi txog cov nqe lus them nqi?

A: Feem ntau EXW LOSSIS FOB Shenzhen 100% T / T ua ntej, thiab peb tuaj yeem sab laj rau koj qhov kev xav tau.