Aerospace Thin-Wall Structural Parts Precision Machining

Hauv kev lag luam aerospace, qhov tseeb tsis yog qhov yuav tsum tau ua xwb - nws yog txoj sia. Nyias-phab ntsa structural qhov chaw, xws li fuselage panels, tis tav tav, thiab cav Cheebtsam, xav tau machining kev txawj ntse uas sib npaug ultra-fine raug nrog cov qauv kev ncaj ncees. Raws li cov chaw tsim khoom lag luam tshwj xeeb hauv aerospace nyias-wall structural parts precision machining, peb muab cov thev naus laus zis thev naus laus zis, kev tswj xyuas zoo, thiab ntau xyoo dhau los ntawm kev xa cov khoom uas ua tau raws li cov qauv thoob ntiaj teb.

Vim li cas thiaj xaiv peb? Advanced Technology Raws li Kev Txawj Ntse

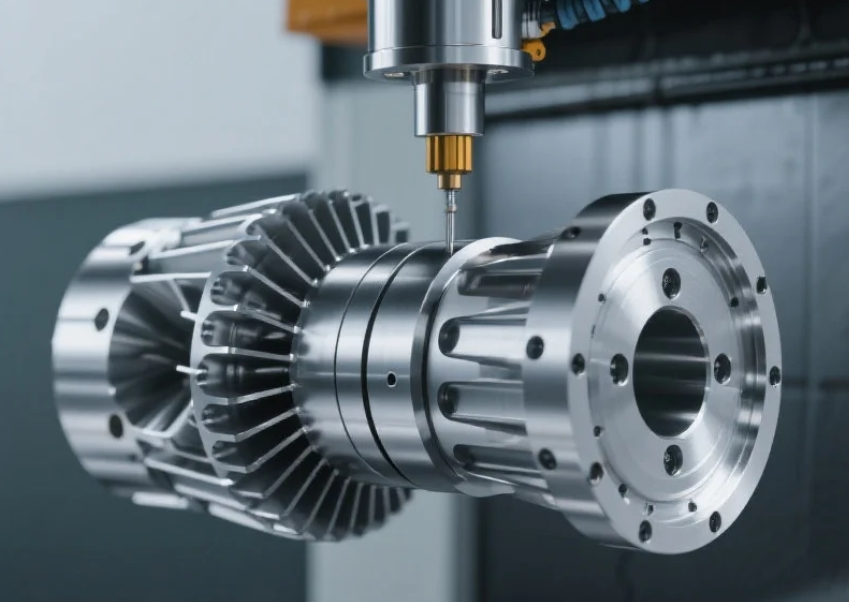

1.State-of-the-Art Equipment: Peb lub chaw yog nruab nrog 5-axis CNC tshuab, high-speed milling (HSM) systems, thiab laser-ultrasonic hybrid ua cov cuab yeej, ua rau peb lis complex geometries thiab ultra-thin phab ntsa (li nyias li 0.5mm) nrog tsawg deformation. Piv txwv li, peb cov cuab yeej HSM ua tiav cov spindle ceev tshaj 15,000 RPM, txo lub sij hawm machining los ntawm 40% thaum txhim kho nto tiav zoo.

2.Proven Machining Solutions: Nyias-phab ntsa aerospace qhov chaw muaj kev co thiab deformation thaum ua. Los ntawm finite element tsom xam (FEA) thiab adaptive machining strategies, peb optimize txiav tsis (xws li, pub tus nqi, qhov tob ntawm txiav) kom txo tau cov kev cov nyom. Peb cov txheej txheem "ntau qhov hloov pauv hloov pauv" cov txheej txheem, tau txais kev tshoov siab los ntawm cov thawj coj hauv kev lag luam xws li AVIC XAC, ua kom qhov tseeb qhov tseeb hauv ± 0.02mm.

3.End-to-End Quality Assurance: Txhua yam khoom siv tau ua tiav peb theem kev soj ntsuam:

● Kev saib xyuas lub sijhawm tiag tiag siv laser scanning rau kev tswj kev deformation.

●CMM (Coordinate Measuring Machine) pov thawj rau qhov tseem ceeb heev.

● Kev ntsuam xyuas qhov ncaj ncees ntawm qhov chaw kom ua tau raws li cov qauv aviation-qib qaug zog tiv thaiv.

Daim ntawv thov: Qhov twg Precision tseem ceeb tshaj plaws

Peb cov kev pab cuam machining haum rau:

●Aircraft Structural Cheebtsam: tis tav, bulkheads, thiab fuselage panels ua los ntawm 7075-T6 txhuas thiab Ti-6Al-4V titanium alloys, optimized rau lub zog-rau-hnyav piv.

●Engine Parts: Turbine hniav thiab casings yuav tsum tau tshav kub-resistant Inconel 718 machining.

●Satellite & Defense Systems: Ultra-lub teeb yuag brackets thiab connectors nrog nruj tolerances.

Kev lag luam-Leading Advantages

● Cov Khoom Siv Siv: Ua kom tau li 95% cov khoom siv tau zoo los ntawm kev ua kom zoo tshaj plaws, txo cov khoom pov tseg thiab cov nqi.

●Rapid Prototyping: Los ntawm CAD tsim rau cov khoom tiav hauv 72 teev, txhawb nqa los ntawm virtual axis machining simulations .

● Kev Txhawb Nqa: Cov kev pabcuam tom qab ua haujlwm muaj xws li anodizing, txhaj tshuaj peening, thiab ntim kev cai kom ntseeg tau tias cov khoom tuaj txog lub davhlau-npaj.

SEO-Optimized Cov ntsiab lus, Cov ntsiab lus zoo sib xws

Txhawm rau txhim kho kev pom zoo rau cov ntsiab lus xws li "aerospace nyias-phab ntsa machining kev pabcuam" thiab "precision CNC machining rau aviation," kab lus no:

●Siv LSI lo lus tseem ceeb (xws li, "high-speed milling," "low-deformation machining") tsis muaj overstuffing .

● Ua raws li Google's EAT cov lus qhia los ntawm kev xa cov qauv kev qhia (xws li ISO 9001, AS9100) thiab cov ntaub ntawv tshawb fawb .

● suav nrog alt-text optimized dluab (piv txwv li, "HSM-machine-aerospace-parts.jpg") rau kev nkag tau zoo dua

Koj tus khub hauv Aerospace Innovation

Nrog 24/7 pab pawg neeg muab kev pabcuam thiab 15-xyoo lav ntawm cov khoom tseem ceeb, peb tau cog lus rau kev koom tes mus ntev. Tshawb nrhiav peb cov ntaub ntawv ntawm 500+ ua tiav cov haujlwm xa mus rau cov neeg siv khoom xws li COMAC thiab Lockheed Martin.

Hu rau peb hnub no los tham txog koj qhov project-vim hauv aerospace machining, tsis muaj chaw rau kev cuam tshuam.

Q: Koj txoj kev lag luam yog dab tsi?

A: OEM Service. Peb qhov kev lag luam yog CNC tshuab dhos ua tiav, tig, stamping, thiab lwm yam.

Q. Yuav tiv tauj peb li cas?

A: Koj tuaj yeem xa cov lus nug ntawm peb cov khoom, nws yuav teb rau hauv 6 teev; Thiab koj tuaj yeem tiv tauj nrog peb ncaj qha los ntawm TM lossis WhatsApp, Skype raws li koj nyiam.

Q.Dab tsi kuv yuav tsum tau muab rau koj rau kev nug?

A: Yog tias koj muaj cov duab kos lossis cov qauv, pls xav tias dawb xa tuaj rau peb, thiab qhia rau peb koj cov kev xav tau tshwj xeeb xws li cov khoom siv, kev ua siab ntev, kev kho deg thiab tus nqi koj xav tau, ect.

Q.Dab tsi txog hnub xa khoom?

A: Hnub xa khoom yog li 10-15 hnub tom qab tau txais cov nyiaj them poob haujlwm.

Q.Dab tsi txog cov nqe lus them nqi?

A: Feem ntau EXW LOSSIS FOB Shenzhen 100% T / T ua ntej, thiab peb tuaj yeem sab laj rau koj qhov kev xav tau.