Aircraft Struts Parts

Advances nyob rau hauv CNC Machining Technology Transforming Manufacturing of Aircraft Strut Parts

Nyob rau hauv lub ntiaj teb complex ntawm aerospace engineering, precision thiab kev ntseeg tau yog qhov tseem ceeb. Aircraft struts yog cov khoom tseem ceeb uas txhawb nqa qhov hnyav ntawm lub dav hlau thaum tsaws thiab hauv av ua haujlwm, thiab xav tau cov qauv tsim khoom siab tshaj plaws. Raws li thev naus laus zis tau hloov zuj zus lawm, kev tswj hwm tus lej hauv computer (CNC) machining tau dhau los ua kev hloov pauv hauv kev tsim cov khoom tseem ceeb no. Qhov tsab xov xwm no tshawb txog yuav ua li cas CNC machining tau revolutionized tsim ntawm aircraft strut qhov chaw, kev txhim kho aviation kev ua tau zoo, kev nyab xeeb, thiab efficiency.

Lub luag haujlwm ntawm CNC Machining hauv Aerospace:

CNC machining tau ntev ua ib feem tseem ceeb ntawm aerospace manufacturing, muab unparalleled precision thiab repeatability. Nyob rau hauv kev tsim cov dav hlau strut qhov chaw, nruj tolerances thiab complex geometries yog tus qauv, thiab CNC machining xyuas kom zoo sib xws thiab zoo nyob rau hauv txhua theem ntawm ntau lawm. Los ntawm kev txhais cov qauv tsim rau hauv lub cev nrog qhov tseeb heev, CNC tshuab ua rau cov kws ua haujlwm hauv aerospace los tsim cov struts uas ua tau raws li cov qauv kev nyab xeeb thiab kev ua tau zoo.

Precision Engineering:

Lub dav hlau strut Cheebtsam, xws li tsaws iav sib dhos thiab hydraulic thooj voos kheej kheej, xav tau kev ua haujlwm nyuaj kom ua tiav qhov yuav tsum tau ua. CNC machining excels hauv cheeb tsam no, raug tsim thiab ua tiav hlau alloys feem ntau siv hauv kev siv aerospace. Txawm hais tias milling, tig los yog sib tsoo, CNC tshuab xa sub-micron raug, xyuas kom txhua qhov ua tau raws li qhov yuav tsum tau ua ntawm tus qauv tsim.

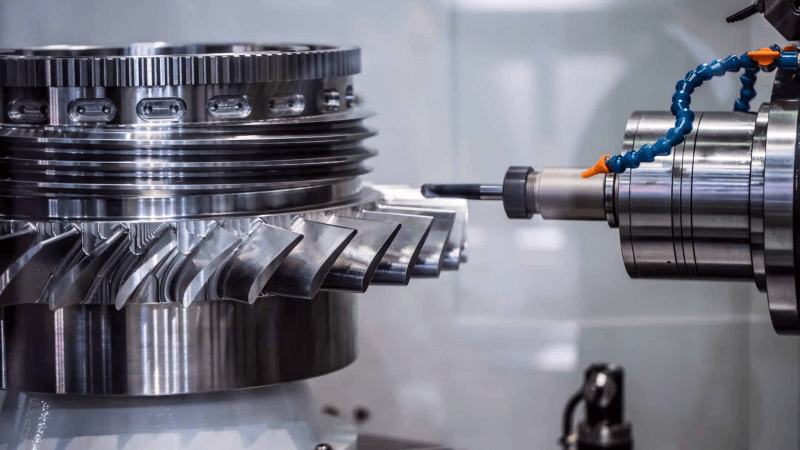

Complex Geometry:

Niaj hnub nimno aircraft struts yog tsim los tiv thaiv lub zog loj heev thaum txo qhov hnyav thiab ua kom muaj kev ncaj ncees zoo tshaj plaws. Qhov no feem ntau yuav tsum tau tsim cov khoom siv nrog cov geometry nyuaj, xws li cov npoo nkhaus, tapered profiles thiab cov kab noj hniav sab hauv. CNC machining muaj peev xwm, suav nrog ntau lub axis machining thiab cov cuab yeej ua haujlwm siab heev, pab kom cov tuam txhab tsim khoom yooj yim tsim cov khoom no. Los ntawm leveraging lub zog ntawm CAD/CAM software, engineers yuav optimize designs rau txhim kho manufacturability thiab streamline ntau lawm txheej txheem.

Khoom Flexibility:

Cov khoom siv dav hlau strut feem ntau yog tsim los ntawm cov ntaub ntawv muaj zog xws li txhuas, titanium thiab stainless hlau los tiv thaiv kev nruj ntawm kev ya davhlau. CNC machining muaj ntau yam tsis sib xws hauv kev ua cov hlau no, tso cai rau kev txiav, drilling thiab sib sau yam tsis muaj kev cuam tshuam cov khoom siv. Txawm hais tias nws yog bulkhead, trunnion lossis piston pas nrig, CNC tshuab tuaj yeem yooj yim lis ntau yam khoom siv, ua kom txhua yam ua tau raws li cov qauv nruj ntawm kev lag luam aerospace.

Quality Assurance:

Hauv kev tsim khoom hauv aerospace, kev tswj kom zoo yog tsis sib tham. Kev cia siab ntawm lub dav hlau thiab kev nyab xeeb yog nyob ntawm kev ncaj ncees ntawm txhua yam khoom, nrog rau cov khoom siv strut. CNC machining plays lub luag haujlwm tseem ceeb hauv kev ua kom muaj kev ruaj ntseg zoo los ntawm kev ua kom lub sijhawm saib xyuas thiab tshuaj xyuas cov khoom siv machined. Nrog cov cuab yeej ntsuas ntsuas siab ua ke hauv CNC tshuab, cov tuam txhab tuaj yeem txheeb xyuas qhov tseeb qhov tseeb, qhov chaw tiav, thiab cov khoom siv ncaj ncees thoob plaws hauv cov txheej txheem tsim khoom, txo qhov kev pheej hmoo ntawm qhov tsis xws luag thiab ua raws li cov qauv kev cai.

Efficiency thiab Nqi-Effectiveness:

Thaum tswj xyuas cov qauv tsis zoo, CNC machining tseem muaj cov txiaj ntsig tseem ceeb ntawm kev ua tau zoo thiab kev ua tau zoo. Los ntawm automating rov ua hauj lwm thiab optimizing machining tsis, manufacturers yuav streamline ntau lawm workflows thiab txo cov sij hawm txhuas. Tsis tas li ntawd, qhov scalability ntawm CNC machining tso cai rau kev tsim cov khoom me me thiab loj ntawm cov khoom siv dav hlau strut, muab kev yooj yim kom tau raws li qhov xav tau ntawm kev lag luam aerospace. Nyob rau lub sijhawm ntev, qhov no txhais tau tias cov nqi tsim khoom qis dua thiab txhim kho kev sib tw rau aerospace manufacturers.

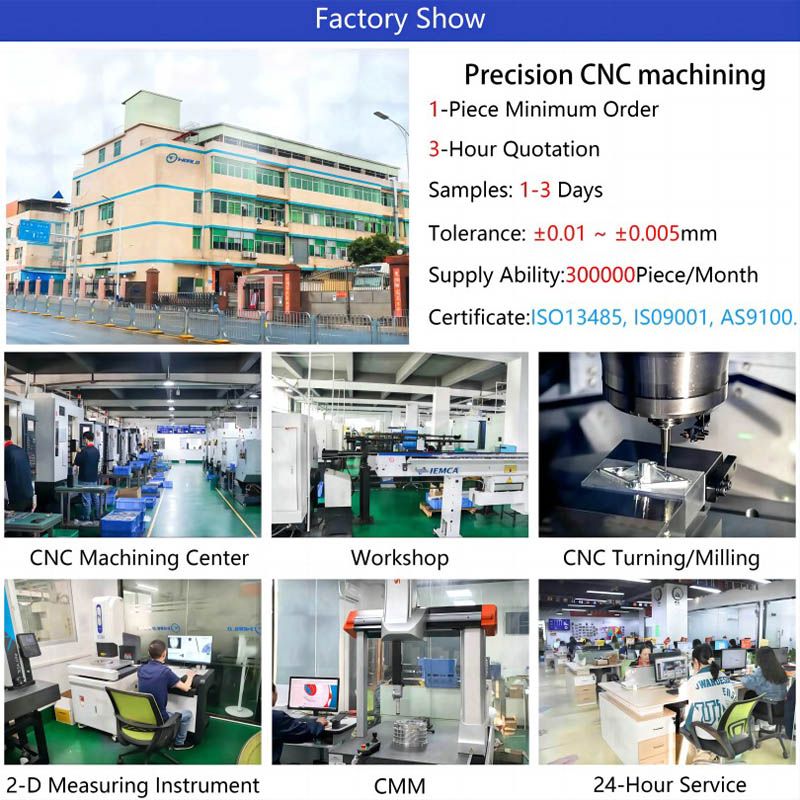

Q: Koj txoj kev lag luam yog dab tsi?

A: OEM Service. Peb qhov kev lag luam yog CNC tshuab dhos ua tiav, tig, stamping, thiab lwm yam.

Q. Yuav tiv tauj peb li cas?

A: Koj tuaj yeem xa cov lus nug ntawm peb cov khoom, nws yuav teb rau hauv 6 teev; Thiab koj tuaj yeem tiv tauj nrog peb ncaj qha los ntawm TM lossis WhatsApp, Skype raws li koj nyiam.

Q.Dab tsi kuv yuav tsum tau muab rau koj rau kev nug?

A: Yog tias koj muaj cov duab kos lossis cov qauv, pls xav tias dawb xa tuaj rau peb, thiab qhia rau peb koj cov kev xav tau tshwj xeeb xws li cov khoom siv, kev ua siab ntev, kev kho deg thiab tus nqi koj xav tau, ect.

Q.Dab tsi txog hnub xa khoom?

A: Hnub xa khoom yog li 10-15 hnub tom qab tau txais cov nyiaj them poob haujlwm.

Q.Dab tsi txog cov nqe lus them nqi?

A: Feem ntau EXW LOSSIS FOB Shenzhen 100% T / T ua ntej, thiab peb tuaj yeem sab laj rau koj qhov kev xav tau.