Customized Hlau Milling, Txiav, thiab Polishing Services

Product Overview

Thaum nws los txog rau kev tsim khoom hlau, precision thiab zoo yog qhov tseem ceeb. Txawm hais tias koj nyob hauv tsheb, aerospace, hluav taws xob, lossis kev lag luam, muaj cov khoom tsim nyog raws li koj qhov kev qhia tshwj xeeb tuaj yeem txhim kho koj cov khoom ua tau zoo. Qhov ntawd yog qhov uas customized hlau milling, txiav, thiab polishing cov kev pab cuam tuaj rau hauv kev ua si. Cov txheej txheem no muab cov kev daws teeb meem rau kev tsim cov khoom zoo, precision-engineered qhov chaw uas ua tau raws li qhov tshwj xeeb xav tau ntawm koj qhov project.

Dab tsi yog Customized Hlau Milling, Txiav, thiab Polishing?

1. Hlau Milling

Milling yog txheej txheem machining uas suav nrog kev siv cov cuab yeej sib hloov kom tshem tawm cov khoom siv los ntawm cov khoom ua haujlwm. Qhov no tso cai rau peb los tsim qhov chaw nrog cov duab nyuaj, qhov ntev meej, thiab cov npoo du. Kev cai hlau milling yog qhov tseem ceeb rau kev tsim cov khoom nrog cov qauv tsim tshwj xeeb thiab tshwj xeeb, txawm tias koj ua haujlwm nrog hlau, txhuas, tooj dag, tooj liab, lossis lwm yam hlau.

• Precision milling yog zoo meej rau kev tsim cov iav, brackets, vaj tse, thiab lwm yam uas yuav tsum tau ua siab ntev.

2. Hlau txiav

Txiav yog ntau yam txheej txheem uas tso cai rau peb los tsim thiab loj hlau raws li koj cov specifications. Qhov no tuaj yeem ua tiav los ntawm ntau txoj hauv kev, xws li laser txiav, plasma txiav, dej dav hlau txiav, thiab shearing. Nyob ntawm cov khoom siv thiab cov qauv tsim, peb xaiv txoj kev txiav kom zoo tshaj plaws kom ua tiav cov txiaj ntsig huv, raug.

•Customized hlau txiav kom ntseeg tau tias txhua qhov haum rau koj tus qauv tsim, txawm tias nws yog ib qho yooj yim txiav los yog cov duab zoo nkauj dua.

3. Hlau Polishing

Polishing yog qhov kawg kov nyob rau hauv tus txheej txheem ntawm customizing hlau qhov chaw. Qhov kev pabcuam no tseem ceeb heev rau kev txhim kho qhov zoo nkauj ntawm qhov chaw thaum tseem txhim kho nws qhov chaw tiav. Polishing tuaj yeem du ntxhib qhov chaw, tshem tawm cov burrs, thiab muab cov sleek, ci tiav rau cov khoom hlau.

•Customized hlau polishing xyuas kom meej tias koj cov khoom tsis yog tsuas yog ua tau zoo tab sis kuj muaj qhov zoo ntawm cov khoom siv rau cov neeg siv khoom siv, xws li cov khoom kim heev, cov khoom siv kho kom zoo nkauj, thiab cov khoom siv kho mob.

Vim li cas thiaj xaiv Customized Hlau Milling, Txiav, thiab Polishing?

• High Precision thiab raug

Kev sib xyaw ua ke ntawm cov cuab yeej siv siab heev thiab cov kws tshaj lij tau tso cai rau peb los tsim cov khoom siv hlau nrog kev ua haujlwm nruj heev. Txawm hais tias nws yog milling lossis txiav, peb cov kev pabcuam tau lees paub qhov tseeb tshaj plaws hauv qhov ntev, kom ntseeg tau tias koj cov khoom haum txig rau hauv koj lub rooj sib dhos lossis tshuab.

•Txoj kev daws teeb meem rau cov kev xav tau tshwj xeeb

Txhua qhov project muaj cov kev xav tau tshwj xeeb, thiab peb cov kev pabcuam hlau customized yog tsim los ua kom tau raws li cov kev xav tau tshwj xeeb. Txawm hais tias koj tab tom tsim cov khoom siv rau cov tshuab ua haujlwm siab, cov tshuab ua haujlwm nyuaj, lossis cov khoom siv khoom kim heev, peb muab cov kev daws teeb meem hloov tau. Los ntawm cov qauv tsim tsis zoo rau qhov ntau thiab tsawg, peb muab cov kev pabcuam zoo los tsim cov khoom zoo meej.

•Multiple Metalworking Techniques nyob rau hauv ib lub ru tsev

Los ntawm kev muab milling, txiav, thiab polishing hauv tsev, peb txhim kho cov txheej txheem ntau lawm thiab txo qhov kev xav tau ntawm outsourcing. Qhov no tsis yog tsuas yog ua kom lub sijhawm hloov pauv sai dua, tab sis kuj tso cai rau kev tswj hwm zoo dua ntawm txhua theem ntawm kev tsim khoom. Txawm hais tias koj tab tom tsim cov qauv tsim lossis kev khiav haujlwm loj, peb muaj peev xwm ua tau txhua yam koj xav tau ua haujlwm hlau.

• Ntau yam khoom xaiv

Peb ua haujlwm nrog ntau yam hlau, suav nrog stainless hlau, txhuas, tooj dag, tooj liab, thiab titanium. Txawm hais tias koj xav tau qhov chaw rau kev siv zog siab lossis cov khoom tiv thaiv corrosion, peb tuaj yeem xaiv cov khoom zoo tshaj plaws rau koj cov kev xav tau tshwj xeeb.

•High-Quality nto tiav

Cov txheej txheem polishing tsis tsuas yog txhim kho qhov zoo nkauj ntawm koj cov khoom tab sis kuj txhim kho corrosion kuj, smoothness, thiab hnav tsis kam. Peb muab ntau hom kev polishing kom phim koj qhov kev xav tau, los ntawm daim iav tiav mus rau satin lossis matte tiav.

•Cov nqi tsim khoom

Customized hlau milling, txiav, thiab polishing cov kev pabcuam tuaj yeem raug nqi ntau dua li cov txheej txheem tsim khoom ib txwm muaj, tshwj xeeb tshaj yog thaum koj tab tom nrhiav rau cov khoom ntim ntau lossis ib qho kev cai. Peb txhim kho cov txheej txheem tsim khoom kom txo tau cov khoom pov tseg thiab txo cov nqi thaum tseem tswj hwm cov txheej txheem siab zoo thiab raug.

Daim ntawv thov tseem ceeb ntawm Customized Hlau Milling, Txiav, thiab Polishing

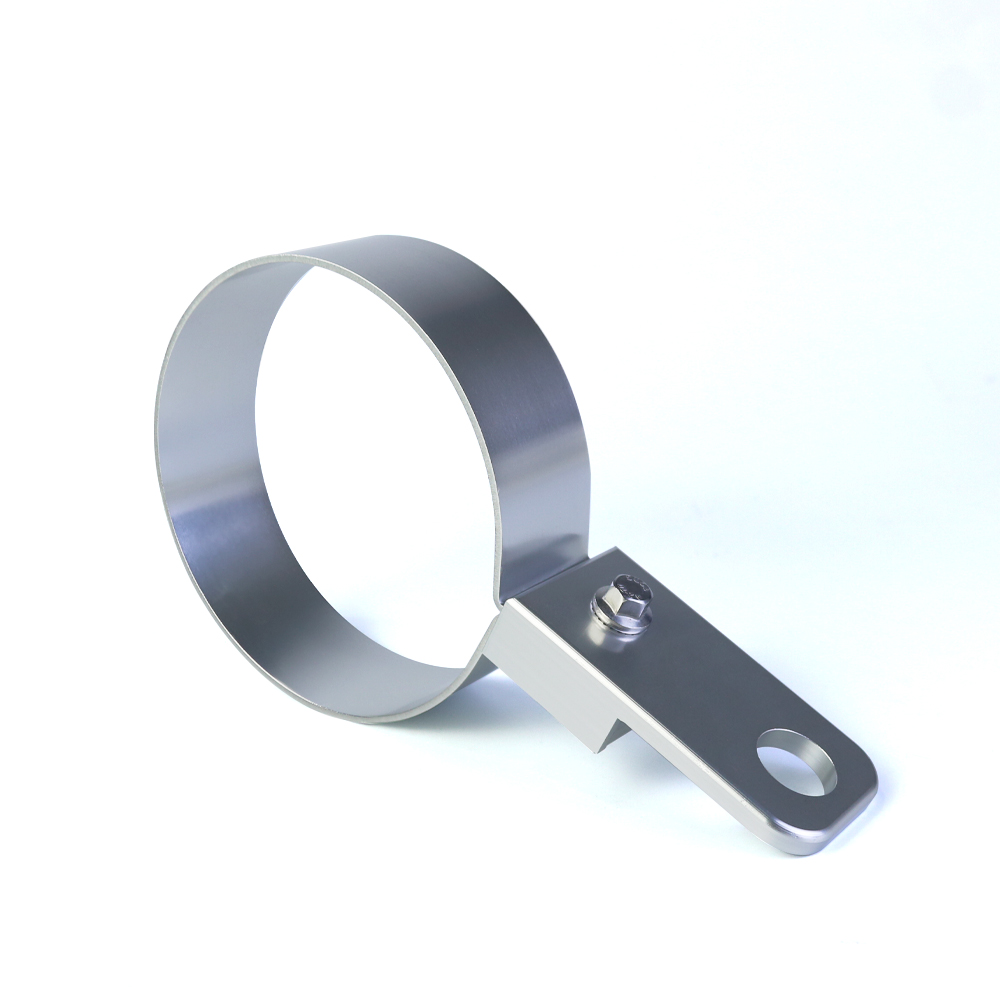

•Automotive Parts

Los ntawm cov khoom siv cav mus rau kev cai brackets thiab vaj tse, hlau milling thiab txiav cov kev pabcuam yog qhov tseem ceeb hauv kev tsim cov khoom siv tsheb. Peb cov kev pabcuam pab tsim cov khoom siv tsheb ua haujlwm siab uas haum txig thiab ua tau raws li qhov xav tau. Peb kuj muab polishing rau qhov chaw uas yuav tsum tau ua kom tiav rau ob qho tib si zoo nkauj thiab ua haujlwm zoo, xws li cov lus qhia tawm lossis cov khoom siv dai kom zoo nkauj.

•Aerospace thiab Aviation

Kev lag luam aerospace xav tau cov khoom siv uas yog ob qho tib si hnav thiab ruaj khov heev. Siv milling, txiav, thiab polishing, peb tsim aerospace qhov chaw xws li dav hlau brackets, tsaws iav Cheebtsam, thiab cav qhov chaw nrog cov qauv tseeb. Peb cov kev pabcuam polishing xyuas kom meej tias cov khoom tseem ceeb tswj lawv cov kev ua tiav kom zoo dua qub thiab txo kev sib txhuam.

• Cov khoom siv hluav taws xob thiab hluav taws xob

Precision yog qhov tseem ceeb thaum tsim cov khoom siv hluav taws xob xws li cov khoom sib txuas, cov dab dej kub, thiab cov vaj tse hauv Circuit Court. Los ntawm customized milling thiab txiav, peb tsim cov khoom kom nruj kam rau ua kom haum zoo kawg nkaus hauv koj cov khoom siv. Cov txheej txheem polishing txhim kho nto conductivity thiab zoo nkauj, tshwj xeeb tshaj yog nyob rau hauv cov neeg siv khoom muag khoom.

• Cov cuab yeej kho mob thiab kho hniav

Kev kho mob thiab kev kho hniav kev lag luam xav tau qhov chaw uas muaj biocompatible thiab meej heev. Milled thiab txiav hlau Cheebtsam yog siv rau hauv cov khoom siv xws li cog, cov cuab yeej phais, thiab cov hniav hniav. Peb cov kev pabcuam polishing pab kom cov khoom no du, tsis muaj burrs, thiab muaj kev nyab xeeb rau kev siv kho mob.

•Industrial Equipment thiab Machinery

Los ntawm cov cuab yeej siv tshuab mus rau lub zog thiab cov ncej, peb muab cov milling customized, txiav, thiab polishing rau ntau yam kev lag luam. Peb cov kev pabcuam pab tsim cov khoom uas ua rau muaj kev kub ntxhov thiab kev hnav siab thaum tswj kev ua haujlwm siab.

• Cov khoom zoo nkauj thiab khoom kim heev

Rau cov khoom uas yuav tsum tau ua tiav high-end, xws li cov khoom kim heev, cov hniav nyiaj hniav kub, lossis cov khoom siv high-end, hlau polishing yog qhov tseem ceeb heev. Peb muab cov kev pabcuam customized kom ua tiav qhov zoo tshaj plaws rau cov khoom no, kom ntseeg tau tias lawv sawv nrog qhov tsis zoo, zoo nkauj zoo nkauj.

Yog tias koj tab tom nrhiav kev ua haujlwm zoo, kho cov hlau milling, txiav, thiab polishing cov kev pabcuam, saib tsis muaj ntxiv. Peb tshwj xeeb hauv kev muab cov khoom siv ua haujlwm zoo rau ntau yam kev lag luam, kom ntseeg tau tias koj cov khoom ua tau raws li cov qauv siab tshaj plaws rau kev ua tau zoo, zoo li, thiab ua haujlwm ntev.

Q1: Hom hlau twg tuaj yeem ua tiav siv cov kev pabcuam no?

A1: Cov kev pabcuam no tsim nyog rau ntau hom hlau, suav nrog: Aluminium Steel (xws li stainless hlau thiab carbon steel) Brass Copper Titanium Nickel Alloys Magnesium Precious Metals (kub, nyiaj, thiab lwm yam) Txawm hais tias koj ua haujlwm nrog cov hlau mos xws li txhuas lossis tawv alloys xws li titanium, cov kev pabcuam hlau customized tuaj yeem ua tau ntau yam khoom siv kom tau raws li koj qhov kev tsim thiab kev ua haujlwm.

Q2: Koj ua li cas kom ntseeg tau qhov zoo hauv kev pabcuam hlau?

A2: Txhawm rau kom tau txais txiaj ntsig zoo, tus kws tshaj lij kev pabcuam feem ntau ua raws li cov kev coj ua no: Kev Siv Tshuab Siab Tshaj Plaws: Siv lub xeev-of-the-art CNC (Computer Numerical Control) milling machines, laser cutters, thiab polishing khoom rau precision thiab sib xws. Kev Ntsuas nruj: Ua cov kev tswj xyuas zoo thoob plaws hauv cov txheej txheem tsim khoom kom paub tseeb tias qhov ntev, qhov ntev, thiab ua tiav. Cov kws tshaj lij kws tshaj lij: Cov kws tshaj lij paub meej tias txhua feem ua tau raws li koj cov kev qhia tshwj xeeb thiab cov qauv kev lag luam. Kev tshuaj xyuas cov khoom: xyuas kom meej tias cov hlau siv yog qhov zoo tshaj plaws, nrog rau cov alloy tsim nyog rau lub zog, corrosion kuj, thiab kev ua haujlwm.

Q3: Lub sijhawm ua haujlwm ntev npaum li cas?

A3: Part Complexity: Ntau cov qauv tsim yuav siv sij hawm ntev dua rau zeb lossis txiav. Kom muaj nuj nqis: Kev txiav txim loj dua feem ntau yuav tsum tau siv sijhawm ntau, tab sis batch ntau lawm tuaj yeem txhim kho kev ua haujlwm. Cov khoom siv: Qee cov hlau ua haujlwm tau yooj yim dua li lwm tus, cuam tshuam rau lub sijhawm tsim khoom. Kev Ua tiav: Polishing tuaj yeem ntxiv sijhawm ntxiv rau cov txheej txheem, nyob ntawm theem ntawm kev ua tiav tiav. Feem ntau, lub sij hawm muaj peev xwm los ntawm ob peb hnub rau cov hauj lwm yooj yim mus rau ob peb lub lis piam rau loj, complex, los yog high-precision txiav txim.

Q4: Koj puas tuaj yeem ua raws li kev cai xaj thiab cov qauv?

A4: Yog lawm, cov kev pabcuam hlau customized yog zoo tagnrho rau ob qho tib si me me-batch ntau lawm thiab prototyping. Txawm hais tias koj xav tau ib-tawm prototypes lossis tab tom npaj rau ntau lawm, cov kev pabcuam no tuaj yeem ua raws li koj cov kev xav tau tshwj xeeb. Ua haujlwm ze nrog cov chaw tsim khoom kom paub meej tias koj cov qauv ua tau raws li qhov xav tau ntawm kev tsim thiab npaj rau kev sim thiab ua kom zoo ntxiv.

Q5: Koj puas tuaj yeem ua haujlwm loj-nqi ntau lawm?

A5: Yog lawm, cov kev pabcuam hlau customized tuaj yeem ua haujlwm rau ob qho tib si me me thiab kev tsim khoom loj. Yog tias koj tab tom npaj ntau lawm, ib tus kws tshaj lij kev pabcuam yuav ua kom zoo dua cov txheej txheem tsim khoom kom zoo thaum tswj xyuas qhov zoo thiab qhov tseeb.