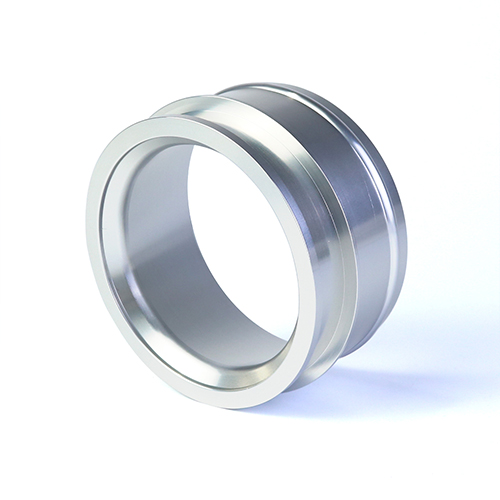

Tshwj xeeb customized CNC machining

1, Cov Khoom Muag Khoom

Tshwj xeeb customized CNC machining yog ib tug high-precision thiab high-efficiency machining kev pab cuam muab kom tau raws li cov neeg xav tau kev pab. Peb siv cov cuab yeej CNC siab heev thiab cov txheej txheem kev paub dhau los los hloov peb cov neeg siv khoom tsim cov tswv yim rau hauv cov khoom zoo. Seb nws yog tus kheej customization los yog loj ntau lawm, peb muaj peev xwm ua tau raws li koj xav tau kev pab nyob rau hauv ntau yam teb nrog zoo heev zoo thiab meej craftsmanship.

2, Khoom nta

(1) Kev kho siab heev

Kev txhawb nqa tus kheej tsim

Peb nkag siab tias txhua tus neeg siv khoom xav tau tshwj xeeb. Yog li ntawd, peb txais tos cov neeg siv khoom los muab lawv tus kheej tsim cov duab kos lossis cov tswv yim tswv yim. Peb pab pawg kws tshaj lij engineering yuav ua haujlwm nrog koj kom nkag siab tob txog koj cov khoom lag luam, cov kev xav tau zoo, thiab kev siv ib puag ncig xav tau. Peb yuav muab koj nrog kev tsim qauv tswv yim thiab optimization daws kom paub meej tias cov khoom kawg ua tau raws li koj qhov kev cia siab.

Saj zawg zog ua technology xaiv

Raws li cov khoom sib txawv thiab cov neeg yuav tsum tau ua, peb tuaj yeem xaiv ntau yam CNC machining txheej txheem, xws li milling, tig, drilling, tho txawv, sib tsoo, hlau txiav, thiab lwm yam. Txawm hais tias nws yog complex 3D nto machining lossis high-precision micro qhov machining, peb tuaj yeem nrhiav txoj hauv kev zoo tshaj plaws machining kom ua tiav qhov kev ua tau zoo thiab zoo ntawm cov khoom.

(2) High precision machining lav

Advanced CNC khoom

Peb tau nruab nrog ib tug series ntawm high-precision CNC machining cov cuab yeej, uas muaj high-resolution tswj systems, meej kis tau tus mob Cheebtsam, thiab ruaj khov tshuab cuab yeej qauv, muaj peev xwm ua kom tiav qib micrometer los yog ntau dua precision machining. Peb tuaj yeem tswj xyuas qhov tseeb ntawm qhov tseeb, cov duab thiab txoj hauj lwm tolerances, thiab nto roughness nyob rau hauv qhov ntau yuav tsum tau los ntawm cov neeg muas zaub, xyuas kom meej tias txhua txhua machining nthuav dav yog meej thiab tsis muaj kev ua yuam kev.

Kev tswj hwm qhov system nruj

Txhawm rau kom muaj kev ruaj ntseg thiab kev ntseeg siab ntawm cov khoom zoo, peb tau tsim kom muaj kev tswj xyuas zoo. Peb nruj me ntsis saib xyuas thiab tswj txhua tus txheej txheem los ntawm kev tshuaj xyuas cov khoom siv raw mus rau qhov kawg tshuaj xyuas cov khoom tiav. Peb siv cov cuab yeej ntsuas thiab cov cuab yeej siv siab heev, xws li kev sib koom ua ke ntsuas tshuab, roughness meters, hardness testers, thiab lwm yam, los ua cov kev ntsuam xyuas thiab kev soj ntsuam ntawm peb cov khoom, xyuas kom meej tias txhua yam khoom xa tuaj rau peb cov neeg muas zaub tau raws li cov qauv zoo.

(3) Kev xaiv cov khoom zoo

Kev xaiv dav ntawm cov ntaub ntawv

Peb muab ntau yam khoom siv, suav nrog ntau yam khoom siv hlau (xws li aluminium alloys, stainless hlau, carbon steel, alloy steel, thiab lwm yam) thiab cov ntaub ntawv tsis yog xim hlau (xws li plastics, ceramics, composite cov ntaub ntawv, thiab lwm yam). Cov neeg siv khoom tuaj yeem xaiv cov ntaub ntawv tsim nyog tshaj plaws raws li cov khoom lag luam kev ua tau zoo, cov nqi xav tau, thiab ib puag ncig yam. Peb tau tsim kom muaj kev sib koom tes ntev thiab ruaj khov kev sib raug zoo nrog ntau tus neeg siv khoom paub zoo los xyuas kom meej qhov zoo thiab ruaj khov ntawm cov khoom siv raw.

Optimization ntawm cov khoom siv

Rau cov ntaub ntawv uas tau xaiv, peb yuav ua raws li pretreatment thiab ua technology optimization raws li lawv cov yam ntxwv. Piv txwv li, rau cov ntaub ntawv aluminium alloy, peb tuaj yeem txhim kho lawv lub zog thiab hardness los ntawm txoj kev xws li kev kho cua sov; Rau cov ntaub ntawv stainless hlau, peb yuav xaiv qhov tsim nyog txiav thiab cov cuab yeej los xyuas kom meej machining efficiency thiab nto zoo. Nyob rau tib lub sijhawm, peb tseem yuav ua qhov kev kho saum npoo ntawm cov ntaub ntawv raws li cov neeg siv khoom xav tau tshwj xeeb (xws li anodizing, electroplating, painting, thiab lwm yam) los txhim kho lawv cov corrosion kuj, hnav tsis kam, thiab zoo nkauj.

(4) Ua haujlwm tau zoo thiab xa khoom sai

Optimized ntau lawm txheej txheem

Peb muaj kev paub ntau lawm pab pawg thiab kev tswj hwm ntau lawm, uas tuaj yeem tshawb fawb thiab tsim nyog teem sijhawm thiab tswj cov haujlwm CNC machining customized. Los ntawm kev ua kom zoo ntawm txoj kev siv thev naus laus zis, txo cov sijhawm ua haujlwm pabcuam, thiab txhim kho kev siv cov cuab yeej siv, peb tuaj yeem ua kom zoo tshaj plaws thiab ua kom cov khoom xa tuaj luv thaum ua kom zoo.

Kev teb sai thiab kev sib txuas lus

Peb tsom mus rau kev sib txuas lus thiab kev koom tes nrog cov neeg siv khoom thiab tau tsim kom muaj kev teb sai sai. Tom qab tau txais cov neeg siv khoom xaj, peb yuav npaj cov neeg ua haujlwm tam sim ntawd los soj ntsuam thiab tshuaj xyuas nws, thiab sib txuas lus nrog cov neeg siv khoom kom paub meej tias cov txheej txheem ua tiav thiab lub sijhawm xa tuaj hauv lub sijhawm luv tshaj plaws. Thaum lub sij hawm cov txheej txheem ntau lawm, peb yuav sai sai muab cov lus teb rau cov neeg siv khoom ntawm qhov kev ua tiav ntawm qhov project, kom ntseeg tau tias lawv tuaj yeem nkag siab txog cov txheej txheem ua haujlwm ntawm cov khoom. Peb yuav teb tam sim ntawd thiab nquag daws txhua yam teeb meem thiab hloov cov lus thov los ntawm cov neeg siv khoom kom ntseeg tau tias qhov kev ua tiav ntawm qhov project.

3 、 Kev siv tshuab

Kev khiav dej num

Kev sib txuas lus thiab kev txheeb xyuas: Sib txuas lus nrog cov neeg siv khoom kom nkag siab txog cov khoom tsim qauv, kev siv lub luag haujlwm, qhov xav tau kom muaj nuj nqis, lub sijhawm xa khoom, thiab lwm yam ntaub ntawv. Ua ib qho kev soj ntsuam ntxaws ntxaws ntawm cov duab kos lossis cov qauv muab los ntawm tus neeg siv khoom, ntsuas qhov ua tau nyuaj thiab ua tau, thiab tsim ib qho kev npaj ua ntej.

Kev tsim kho kom zoo thiab kev pom zoo: Raws li cov neeg siv khoom xav tau thiab ua cov txheej txheem thev naus laus zis, txhim kho thiab txhim kho cov khoom tsim. Rov qab sib txuas lus thiab paub meej nrog cov neeg siv khoom kom ntseeg tau tias qhov kev thov tsim ua tau raws li lawv qhov kev cia siab. Yog tias tsim nyog, peb tuaj yeem muab cov neeg siv khoom nrog 3D qauv thiab simulated machining ua qauv qhia kom lawv nkag siab ntau dua ntawm cov khoom siv machining txheej txheem thiab cov nyhuv kawg.

Cov txheej txheem kev npaj thiab kev ua haujlwm: Raws li kev txiav txim siab tsim qauv thiab cov kev xav tau ntawm machining, xaiv cov khoom siv CNC machining tsim nyog thiab cov cuab yeej, thiab tsim cov txheej txheem machining cov txheej txheem thiab cov kev txiav. Siv cov kev tshaj lij programming software los tsim CNC machining cov kev pab cuam thiab ua simulation pov thawj los xyuas kom meej qhov tseeb thiab ua tau ntawm cov kev pab cuam.

Kev npaj thiab ua cov khoom siv: Npaj cov khoom siv raw raws li cov txheej txheem yuav tsum tau ua, thiab ua nruj soj ntsuam thiab pretreatment. Nruab cov ntaub ntawv raw ntawm CNC machining cov cuab yeej thiab ua lawv raws li qhov kev pab cuam sau. Thaum lub sijhawm ua haujlwm, cov neeg ua haujlwm saib xyuas cov cuab yeej kev ua haujlwm thiab cov txheej txheem ua haujlwm hauv lub sijhawm tiag tiag kom ntseeg tau tias kev ua haujlwm ruaj khov thiab ua haujlwm tau zoo.

Kev tshuaj xyuas thiab kev tswj xyuas zoo: Ua tiav kev tshuaj xyuas zoo ntawm cov khoom ua tiav, suav nrog qhov ntsuas qhov tseeb, qhov zoo thiab qhov ntsuas qhov ntsuas siab, kev tshuaj xyuas qhov zoo ntawm qhov chaw, ntsuas qhov tawv, thiab lwm yam. Ua cov kev soj ntsuam zoo thiab kev soj ntsuam raws li qhov ntsuas tau, thiab kho tam sim ntawd thiab kho cov khoom tsis zoo.

Kev kho deg thiab kev sib dhos (yog tias tsim nyog): Kev kho deg ntawm cov khoom yog ua raws li cov neeg siv khoom xav tau, xws li anodizing, electroplating, painting, polishing, thiab lwm yam., txhawm rau txhim kho cov tsos zoo thiab corrosion kuj ntawm cov khoom. Rau cov khoom uas yuav tsum tau sib dhos, ntxuav, tshuaj xyuas, thiab sib sau ua ke cov khoom, thiab ua raws li kev debugging thiab kuaj kom paub meej tag nrho cov kev ua tau zoo thiab zoo ntawm cov khoom.

Kev ntim khoom tiav thiab xa khoom tiav: Ua tib zoo ntim cov khoom uas tau dhau los soj ntsuam, siv cov khoom ntim tsim nyog thiab cov txheej txheem los xyuas kom meej tias cov khoom tsis puas thaum lub sijhawm thauj mus los. Xa cov khoom tiav rau cov neeg siv khoom raws li lub sijhawm xa khoom pom zoo thiab txoj hauv kev, thiab muab cov ntaub ntawv soj ntsuam xyuas zoo thiab cov lus cog tseg tom qab muag.

Cov ntsiab lus tseem ceeb ntawm kev tswj kom zoo

Kev tshuaj xyuas cov khoom siv raw: Ua nruj soj ntsuam ntawm txhua pawg ntawm cov khoom siv raw, suav nrog kev sim ntawm lawv cov tshuaj muaj pes tsawg leeg, cov khoom siv kho tshuab, qhov tseeb qhov tseeb, thiab lwm yam. Xyuas kom meej tias cov ntaub ntawv raw ua tau raws li lub teb chaws cov qauv thiab cov neeg siv khoom, thiab lav cov khoom zoo los ntawm qhov chaw.

Kev saib xyuas cov txheej txheem: Kev saib xyuas lub sijhawm tiag tiag thiab sau cov txheej txheem tseem ceeb thiab cov txheej txheem ua haujlwm thaum lub sijhawm CNC machining. Tsis tu ncua tswj thiab tu cov cuab yeej kom ntseeg tau tias nws raug thiab ruaj khov. Los ntawm kev sib txuas thawj tsab xov xwm tshuaj xyuas, kev soj ntsuam xyuas, thiab kev tshuaj xyuas tiav, cov teeb meem uas tshwm sim thaum lub sijhawm ua haujlwm raug txheeb xyuas tam sim thiab daws kom ntseeg tau tias qhov sib xws thiab ruaj khov ntawm cov khoom zoo.

Calibration ntawm cov cuab yeej kuaj: Tsis tu ncua calibrate thiab calibrate cov cuab yeej xeem thiab cov cuab yeej siv los xyuas kom meej qhov tseeb thiab kev ntseeg siab ntawm cov ntaub ntawv xeem. Tsim cov ntaub ntawv tswj xyuas cov cuab yeej ntsuas, sau cov ntaub ntawv xws li lub sijhawm ntsuas ntsuas, ntsuas ntsuas ntsuas, thiab siv cov cuab yeej siv rau kev taug qab thiab tswj xyuas.

Kev cob qhia cov neeg ua haujlwm thiab kev tswj hwm: Txhim kho kev cob qhia thiab kev tswj xyuas cov neeg ua haujlwm thiab cov neeg soj ntsuam zoo, txhim kho lawv cov kev txawj ntse thiab kev paub zoo. Cov neeg ua haujlwm yuav tsum tau txais kev cob qhia nruj thiab kev ntsuam xyuas, paub txog kev ua haujlwm thiab kev ua haujlwm ntawm cov cuab yeej CNC, thiab paub txog cov ntsiab lus tseem ceeb thiab cov txheej txheem ntawm kev tswj kom zoo. Cov kws tshuaj ntsuam xyuas zoo yuav tsum muaj kev paub dhau los thiab kev paub txog kev tshaj lij, thiab muaj peev xwm txiav txim siab seb cov khoom zoo li cas.

Q: Dab tsi yog cov txheej txheem tshwj xeeb rau customizing CNC machining khoom?

Teb: Ua ntej, koj tuaj yeem tiv tauj peb hauv xov tooj, email, lossis kev sib tham hauv online los piav qhia koj cov khoom xav tau, suav nrog cov yam ntxwv, qhov ntev, cov duab, cov ntaub ntawv, qhov ntau, qhov xav tau precision, thiab lwm yam. Koj tuaj yeem muab cov qauv tsim lossis qauv. Peb pab neeg tshaj lij yuav ua qhov kev ntsuam xyuas ua ntej thiab kev tshuaj xyuas thaum tau txais koj cov kev xav tau, thiab sib txuas lus nrog koj kom paub meej cov ntsiab lus tseem ceeb. Tom ntej no, peb yuav tsim cov txheej txheem ua tiav thiab cov lus hais raws li koj xav tau. Yog tias koj txaus siab rau txoj kev npaj thiab hais lus, peb yuav kos npe rau daim ntawv cog lus thiab npaj ntau lawm. Thaum lub sijhawm tsim khoom, peb yuav muab cov lus qhia rau koj tam sim ntawd txog qhov kev ua tiav ntawm qhov project. Tom qab kev tsim khoom tiav, peb yuav ua cov kev soj ntsuam nruj kom ntseeg tau tias cov khoom ua tau raws li koj xav tau ua ntej xa khoom.

Q: Kuv tsis muaj cov duab kos duab, tsuas yog lub tswv yim khoom xwb. Koj puas tuaj yeem pab kuv tsim thiab ua nws?

Teb: Tau kawg. Peb muaj ib pab pawg kws tshaj lij ntawm cov kws tsim qauv tsim nrog kev paub nplua nuj thiab kev paub txog kev paub, uas tuaj yeem tsim thiab tsim raws li cov khoom lag luam cov ntsiab lus koj muab. Peb yuav muaj kev sib txuas lus tob nrog koj kom nkag siab txog koj cov kev xav tau thiab cov tswv yim, thiab tom qab ntawd siv cov software tsim kev tshaj lij rau 3D qauv thiab tsim kom zoo tshaj plaws los muab cov ncauj lus kom ntxaws tsim thiab cov duab kos rau koj. Thaum lub sij hawm tus txheej txheem tsim, peb yuav tsis tu ncua sib txuas lus thiab paub meej nrog koj kom paub meej tias cov qauv tsim raws li koj xav tau. Tom qab tsim tiav, peb yuav ua raws li cov txheej txheem kev ua haujlwm raws li kev tsim khoom thiab kev ua haujlwm.

Q: Cov ntaub ntawv dab tsi koj tuaj yeem ua tau?

Teb: Peb tuaj yeem ua ntau yam ntaub ntawv, suav nrog cov khoom siv hlau xws li aluminium alloy, stainless hlau, carbon steel, alloy steel, tooj liab, nrog rau cov ntaub ntawv tsis yog xim hlau xws li yas, nylon, acrylic, ceramics, thiab lwm yam. Peb yuav muab cov txheej txheem kev ua haujlwm thiab cov lus pom zoo raws li cov ntaub ntawv koj xaiv.

Q: Kuv yuav ua li cas yog tias kuv pom cov teeb meem zoo nrog cov khoom tom qab tau txais nws?

Teb: Yog tias koj pom muaj teeb meem zoo nrog cov khoom tom qab tau txais nws, thov hu rau peb tam sim ntawd thiab peb yuav pib qhov kev daws teeb meem zoo sai li sai tau. Peb yuav xav kom koj muab cov duab, yeeb yaj kiab, lossis cov ntawv ceeb toom cuam tshuam kom peb tuaj yeem txheeb xyuas thiab ntsuas qhov teeb meem. Yog tias nws yog peb qhov teeb meem zoo, peb yuav ua lub luag haujlwm sib xws thiab muab cov kev daws teeb meem pub dawb rau koj xws li kev kho, hloov, lossis nyiaj rov qab. Peb yuav daws koj qhov teeb meem sai li sai tau kom paub meej tias koj cov cai raug tiv thaiv.

Q: Lub voj voog ntau lawm ntev npaum li cas rau cov khoom lag luam customized feem ntau siv?

Teb: Lub voj voog ntau lawm yog cuam tshuam los ntawm ntau yam, xws li qhov nyuaj ntawm cov khoom, kev siv tshuab, kom muaj nuj nqis, cov khoom siv, thiab lwm yam. Feem ntau hais lus, lub voj voog ntau lawm rau cov khoom lag luam customized yooj yim yuav nyob ib ncig ntawm 1-2 lub lis piam; Rau cov khoom lag luam lossis kev txiav txim loj loj, lub voj voog ntau lawm yuav txuas ntxiv mus rau 3-4 lub lis piam lossis ntev dua. Thaum koj nug, peb yuav muab rau koj nrog kwv yees kwv yees ntau lawm voj voog raws li koj cov khoom tshwj xeeb. Nyob rau tib lub sijhawm, peb yuav ua txhua yam los txhim kho cov txheej txheem ntau lawm, ua kom lub voj voog ntau lawm, thiab xyuas kom meej tias koj tuaj yeem tau txais cov khoom sai li sai tau.