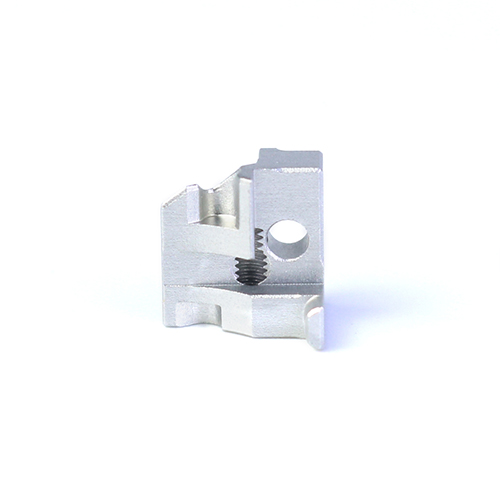

High-quality kev cai precision milled qhov chaw

Product Overview

Nyob rau hauv lub ntiaj teb no ntawm kev tsim, precision CNC milling qhov chaw pabcuam plays lub luag haujlwm tseem ceeb hauv kev xa cov khoom zoo, kev cai tsim rau ntau hom kev lag luam. Txawm hais tias koj nyob hauv aerospace, automotive, electronics, lossis kev kho mob, CNC milling ua kom tsis muaj qhov tseeb, kev ua tau zoo, thiab hloov pauv rau koj cov haujlwm.

Tshawb nrhiav yog vim li cas peb cov precision CNC milling qhov kev pabcuam yog qhov kev xaiv zoo tshaj plaws rau cov neeg siv khoom nrhiav kev ua haujlwm zoo hauv machining thiab peb tuaj yeem coj koj cov tswv yim rau lub neej nrog precision-crafted qhov chaw.

Dab tsi yog Precision CNC Milling?

CNC milling (Computer Numerical Control milling) yog cov txheej txheem tsim tawm uas cov cuab yeej txiav cov cuab yeej tshem tawm cov khoom los ntawm cov khoom ua haujlwm los tsim cov duab thiab cov yam ntxwv. Tsis zoo li cov qauv txheej txheem, CNC milling muaj qhov tseeb tshwj xeeb, rov ua dua, thiab muaj peev xwm los daws cov duab geometry.

Peb precision CNC milling kev pab cuam tshwj xeeb hauv kev tsim cov khoom nrog nruj tolerances, complex designs, thiab ntau yam ntawm cov ntaub ntawv, kom ntseeg tau tias koj cov kev cai tshwj xeeb tau ntsib nrog unmatched zoo.

Qhov zoo ntawm peb cov Precision CNC Milling Parts Service

1.Unrivaled raug

Peb lub xeev-ntawm-lub-kos duab CNC milling tshuab xa cov khoom nrog kam rau ua nruj raws li ± 0.01mm, kom ntseeg tau precision rau txawm lub feem ntau complex designs.

2. Kev xaiv dav dav

Peb zeb ntau yam ntaub ntawv, xws li txhuas, stainless hlau, titanium, tooj dag, yas, thiab lwm yam. Txhua yam khoom yog ua tib zoo xaiv raws li koj qhov project specifications.

3.Complex Geometry

Los ntawm cov chaw tiaj tus yooj yim rau cov duab 3D sib txawv, peb lub peev xwm CNC milling tuaj yeem ua haujlwm txawm tias cov qauv tsim nyuaj tshaj plaws nrog kev yooj yim.

4.Cov kev daws teeb meem zoo

Los ntawm kev siv cov thev naus laus zis siab heev, peb txhim kho cov txheej txheem tsim khoom kom txo qis thiab txo cov nqi tsim khoom yam tsis muaj kev cuam tshuam zoo.

5. Kev ua tiav tiav

Txhim khu lub durability thiab zoo nkauj ntawm koj qhov chaw nrog tiav zoo li anodizing, polishing, hmoov txheej, los yog sandblasting.

6. Lub Sijhawm Ua Haujlwm nrawm

Peb cov txheej txheem ntau lawm kom ntseeg tau tias koj cov khoom xa tuaj raws sijhawm, txhua lub sijhawm, txawm tias rau kev tsim khoom lossis kev tsim khoom loj.

Kev siv ntawm Precision CNC Milling Parts

Peb cov kev pabcuam CNC milling ua haujlwm rau ntau yam kev lag luam thiab kev siv, suav nrog:

1.Aerospace Cheebtsam

Lub teeb tab sis muaj zog qhov chaw xws li brackets, vaj tse, thiab cov khoom siv.

2.Automotive Parts

Cov khoom siv tshwj xeeb xws li cov khoom siv cav, cov khoom sib kis, thiab cov tshuab raug tshem tawm.

3. Cov khoom siv kho mob

High-precision surgical instruments, implantable devices, thiab cov cuab yeej kuaj mob.

4.Electronics

Kev cai enclosures, heat sinks, thiab connectors rau electronic devices.

5. Cov Khoom Siv Hluav Taws Xob

Precision-milled qhov chaw xws li iav, clamps, thiab mounting brackets.

6.Robotics

Cheebtsam rau robotic caj npab, precision pob qij txha, thiab automation systems.

Peb cov txheej txheem ua haujlwm li cas

1.Kev sab laj & Tsim Kev Tshawb Fawb

Qhia koj cov ntaub ntawv tsim lossis cov lus qhia tshwj xeeb nrog peb. Peb engineers yuav tshuaj xyuas lawv rau manufacturability thiab qhia optimization yog tias xav tau.

2. Kev xaiv khoom

Xaiv los ntawm ntau yam ntaub ntawv uas haum rau koj daim ntawv thov. Peb muab cov kws tshaj lij cov lus pom zoo los xyuas kom meej cov txiaj ntsig zoo tshaj plaws.

3. Precision Milling

Peb cov tshuab CNC pib tsim cov txheej txheem, xa cov khoom nrog qhov tseeb tshwj xeeb thiab sib xws.

4.Nto tiav

Customize koj cov khoom nrog kev ua tiav uas txhim kho durability, zoo li, thiab kev ua haujlwm.

5.Kev soj ntsuam zoo

Txhua qhov chaw raug tshuaj xyuas kom zoo rau qhov tseeb qhov tseeb, cov khoom zoo, thiab qhov chaw tiav.

6.Kev xa khoom

Thaum pom zoo, koj cov khoom tau ntim khoom ruaj ntseg thiab xa mus rau koj qhov chaw.

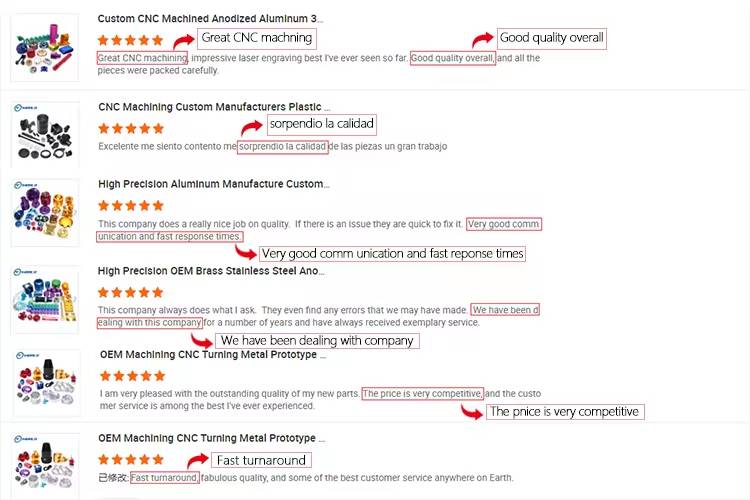

Koom tes nrog peb rau koj CNC Milling xav tau

Thaum nws los txog rau precision CNC milling qhov chaw pabcuam, peb txoj kev cog lus rau kev ua tau zoo ua rau peb sib nrug. Nrog rau kev tsom mus rau qhov zoo, kev ua tau zoo, thiab kev txaus siab ntawm cov neeg siv khoom, peb xa cov khoom uas tsis yog tsuas yog ua tau raws li koj xav tau, tab sis tshaj qhov koj xav tau.

Q: Dab tsi customization xaiv muaj rau precision milled qhov chaw?

A: Peb muab tag nrho cov kev daws teeb meem customizable, suav nrog:

Kev xaiv cov khoom siv: Ntau hom hlau thiab yas.

Complex geometry: Muaj peev xwm tsim cov qauv tsim.

Tolerances: Ua tiav nruj tolerances ntawm ± 0.01mm los yog zoo dua.

Nto tiav: Cov kev xaiv zoo li anodizing, plating, polishing, thiab sandblasting.

Tshwj xeeb nta: Xov, qhov, grooves, los yog ntau qhov chaw machining.

Q: Cov ntaub ntawv dab tsi koj tuaj yeem ua haujlwm nrog rau kev cai milled qhov chaw?

A: Peb ua haujlwm nrog ntau yam khoom siv kom tau raws li cov kev xav tau tshwj xeeb, suav nrog:

Hlau: Aluminium, stainless hlau, titanium, tooj dag, tooj liab, thiab hlau alloys.

Plastics: ABS, polycarbonate, POM (Delrin), nylon, thiab lwm yam.

Cov ntaub ntawv tshwj xeeb: Magnesium, Inconel, thiab lwm yam kev ua haujlwm siab.

Q: Dab tsi yog qhov siab tshaj plaws ntawm qhov chaw koj tuaj yeem zeb?

A: Peb tuaj yeem zeb qhov chaw nrog qhov ntev txog li 1,000mm x 500mm x 500mm, nyob ntawm cov khoom siv thiab cov qauv tsim.

Q: Koj puas tuaj yeem tsim cov qauv ua ntej ntau lawm?

A: Yog lawm, peb muab cov kev pabcuam prototyping sai kom ntseeg tau tias tus qauv tsim ua tau raws li txhua yam kev ua haujlwm thiab kev zoo nkauj ua ntej kev tsim khoom puv.

Q: Koj lub sijhawm ntau lawm yog dab tsi?

A: Peb lub sijhawm ntau lawm nyob ntawm qhov nyuaj thiab kev txiav txim ntim:

Prototyping: 5-10 hnub ua haujlwm

Ntau lawm: 2-4 lub lis piam

Q: Puas yog koj qhov chaw milled eco-phooj ywg?

A: Peb tau cog lus rau kev ruaj khov thiab muaj:

Eco-phooj ywg cov ntaub ntawv

Cov txheej txheem tsim khoom pov tseg tsawg tsawg

Cov kev pabcuam rov ua dua tshiab rau cov khoom siv hlau

Q: Dab tsi saum npoo tiav koj tuaj yeem muab rau qhov chaw milled?

A: Peb muab ntau yam kev kho mob saum npoo los txhim kho cov kav ntev, zoo li, thiab kev ua haujlwm, suav nrog:

Anodizing (ntshiab los yog xim)

Electroless npib tsib xee plating

Chrome plating

Hmoov txheej

Polishing, sandblasting, los yog hlaws blasting

Q: Koj ua li cas kom ntseeg tau qhov zoo ntawm koj qhov chaw milled?

A: Peb siv cov txheej txheem tswj xyuas kom zoo, suav nrog:

Kev tshuaj xyuas qhov ntev: Siv cov cuab yeej ntsuas qib siab zoo li CMMs.

Cov ntaub ntawv pov thawj: Ua kom cov ntaub ntawv raw ua tau raws li cov qauv kev lag luam.

Kev sim ua haujlwm: Rau qhov tseem ceeb ntawm kev ua haujlwm.