Hlau qhov chaw rau Industrial Robotics

Taw qhia

Hauv kev nce qib sai ntawm kev lag luam neeg hlau, qhov tseem ceeb ntawm cov khoom hlau zoo tsis tuaj yeem overstated. Cov khoom no yog qhov tseem ceeb rau kev ua kom muaj txiaj ntsig, ua haujlwm ntev, thiab kev ua kom zoo hauv kev siv neeg hlau. Nyob rau hauv tsab xov xwm no, peb yuav tshawb txog ntau yam ntawm cov khoom siv hlau siv hauv kev lag luam neeg hlau, lawv cov txiaj ntsig, thiab lawv pab txhawb rau kev hloov pauv ntawm automation li cas.

Nkag siab txog Metal Parts hauv Robotics

Cov khoom siv hlau yog qhov tseem ceeb rau cov qauv thiab kev ua haujlwm ntawm kev lag luam robots. Lawv feem ntau yog tsim los ntawm cov ntaub ntawv xws li steel, aluminium, thiab titanium, txhua qhov muab cov khoom tshwj xeeb uas txhim kho kev ua haujlwm zoo.

· Hlau: Paub txog nws lub zog thiab ua haujlwm ntev, steel feem ntau yog siv rau hauv cov haujlwm hnyav uas qhov kev ua haujlwm ruaj khov yog qhov tseem ceeb.

·Aluminium: Lub teeb yuag thiab corrosion-resistant, aluminium qhov chaw yog qhov zoo tagnrho rau cov ntawv thov uas txo qhov hnyav yog qhov tseem ceeb yam tsis muaj kev cuam tshuam lub zog.

·Titanium: Txawm hais tias kim dua, titanium qhov chaw muaj qhov tshwj xeeb ntawm lub zog-rau-qhov hnyav thiab siv rau hauv cov ntawv tshwj xeeb.

Qhov tseem ceeb hlau qhov chaw rau Industrial Robotics

1.Ncej thiab Chassis

Lub caj qaum ntawm txhua qhov kev siv tshuab hlau, hlau thav duab muab kev txhawb nqa tsim nyog thiab kev ruaj ntseg. Lawv tau tsim los tiv thaiv kev nruj ntawm kev lag luam ib puag ncig.

2.Joints thiab Connectors

Hlau pob qij txha pab txhawb kev txav thiab yoog raws hauv cov caj npab robotic. High-quality hlau connectors kom precision nyob rau hauv kev khiav hauj lwm thiab ntev nyob rau hauv kev ua tau zoo.

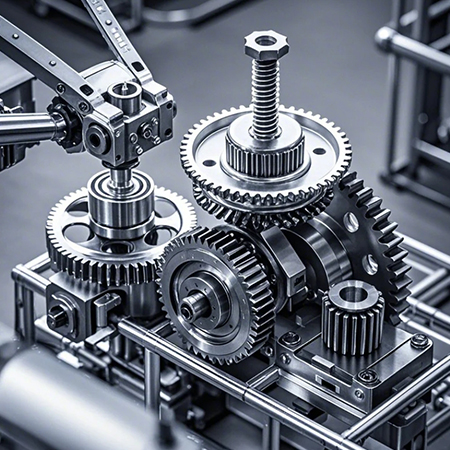

3.Gears thiab Tsav Cheebtsam

Cov iav hlau yog qhov tseem ceeb rau kev hloov cov lus tsa suab thiab lub zog hauv tus neeg hlau. Lawv cov kav ntev yog qhov tseem ceeb rau kev tswj xyuas kev ua haujlwm ntawm lub sijhawm.

4.End Effectors

Feem ntau ua los ntawm cov hlau, qhov kawg effectors (los yog grippers) yog qhov tseem ceeb rau kev ua haujlwm. Lawv yuav tsum muaj zog tsis tau meej los tuav ntau yam ntaub ntawv hauv kev lag luam.

Cov txiaj ntsig ntawm Cov Hlau Hlau hauv Industrial Robotics

· Durability: Cov khoom siv hlau tsis tshua hnav thiab tsim kua muag, ua kom lub neej ntev dua rau cov tshuab neeg hlau.

·Precision: Cov khoom siv hlau zoo tshaj plaws txhim kho qhov tseeb ntawm cov neeg hlau txav, ua rau kev ua haujlwm zoo dua hauv kev tsim khoom.

·Kev kho kom haum: Ntau lub tuam txhab muab cov kev daws teeb meem, tso cai rau cov lag luam tuaj yeem kho cov khoom siv hlau kom haum rau cov kev siv neeg hlau tshwj xeeb.

Raws li kev ntseeg siabprecision CNC machining qhov chaw Hoobkas, peb tau cog lus tias yuav xa cov khoom tshwj xeeb uas ua tau raws li qhov xav tau ntawm kev tsim khoom niaj hnub no. Peb tsom rau qhov zoo, precision, thiab cov neeg siv khoom txaus siab muab peb sib nrug hauv kev lag luam. Tiv tauj peb hnub no kom paub ntau ntxiv txog peb cov kev pabcuam CNC machining thiab nrhiav seb peb tuaj yeem pab txhawb koj cov txheej txheem tsim khoom li cas!

Hu rau Action

Yog tias koj txaus siab rau cov khoom siv hlau zoo rau koj daim ntawv thov kev lag luam robotic, tiv tauj peb hnub no! Peb cov kws tshaj lij hauv kev tsim cov khoom ruaj khov thiab meej yuav pab koj ua tiav koj lub hom phiaj automation.

Q: Koj txoj kev lag luam yog dab tsi?

A: OEM Service. Peb qhov kev lag luam yog CNC tshuab dhos ua tiav, tig, stamping, thiab lwm yam.

Q. Yuav tiv tauj peb li cas?

A: Koj tuaj yeem xa cov lus nug ntawm peb cov khoom, nws yuav teb rau hauv 6 teev; Thiab koj tuaj yeem tiv tauj nrog peb ncaj qha los ntawm TM lossis WhatsApp, Skype raws li koj nyiam.

Q.Dab tsi kuv yuav tsum tau muab rau koj rau kev nug?

A: Yog tias koj muaj cov duab kos lossis cov qauv, pls xav tias dawb xa tuaj rau peb, thiab qhia rau peb koj cov kev xav tau tshwj xeeb xws li cov khoom siv, kev ua siab ntev, kev kho deg thiab tus nqi koj xav tau, ect.

Q.Dab tsi txog hnub xa khoom?

A: Hnub xa khoom yog li 10-15 hnub tom qab tau txais cov nyiaj them poob haujlwm.

Q.Dab tsi txog cov nqe lus them nqi?

A: Feem ntau EXW LOSSIS FOB Shenzhen 100% T / T ua ntej, thiab peb tuaj yeem sab laj rau koj qhov kev xav tau.