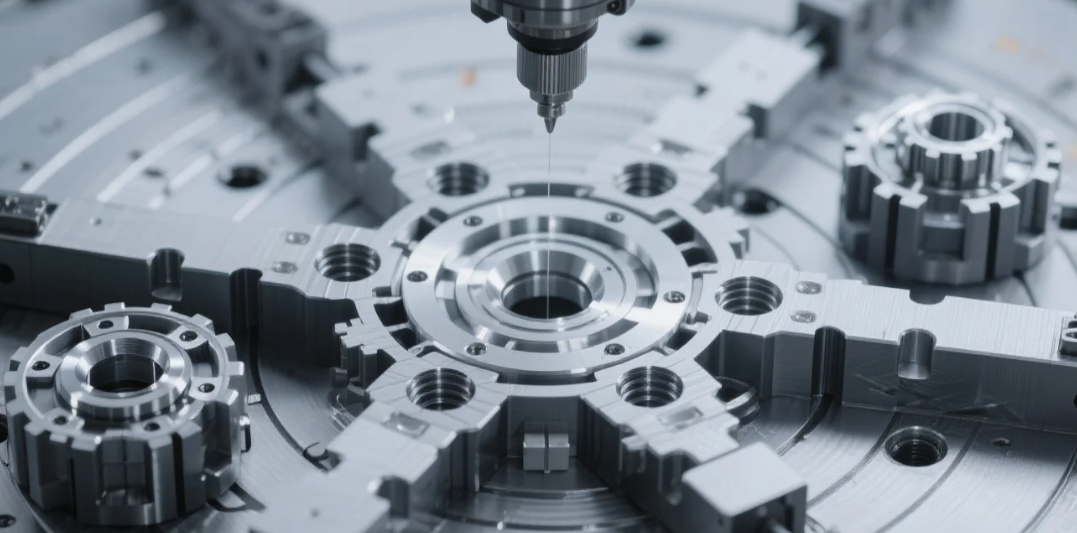

Multi-Axis CNC Machining rau Ultra-Precision Optical Cheebtsam nrog Complex Geometry

Hauv kev lag luam qhov twg micron-theem qhov tseeb txhais tau tias muaj kev vam meej - aerospace, cov cuab yeej kho mob, cov khoom siv kho qhov muag - qhov kev thov rauultra-precision optical Cheebtsamnrogcomplex geometryyog surging. Cov tsoos 3-axis CNC tshuab tawm tsam nrog intricate contours thiab nruj tolerances, tab sisMulti-axis CNC machiningrevolutionizes qhov no. Peb lub Hoobkas leverages txiav-ntug 5-axis CNC tshuab xa cov khoom uas ua tau raws li cov qauv nruj tshaj plaws, sib txuascov cuab yeej siv siab heev,kev tswj kom zoo, thiabkev txhawb nqa cov neeg siv khoom.

Vim li cas Multi-Axis CNC Machining?

1.Unmatched Precision rau Complex Designs

• Tsis zoo li 3-axis tshuab txwv rau kev txav tawm, peb5-axis CNC tshuab(piv txwv li, DMU series) pab kom muaj kev sib hloov ib txhij raws A / B / C axes. Qhov no tso cai rau machining complex duab-freeform lo ntsiab muag, aspherical tsom iav-nyob rau hauv ib qho kev teeb tsa, tshem tawm repositioning yuam kev thiab ua tau raws li kam rau ua nyob rau hauv± 0.003 hli.

• Piv txwv li: Lub lens dual-curvature rau laser collimators, yuav tsum tau <0.005mm deviation deg, tau tsim nrog 99.8% raug.

2.Kev ua tau zoo & kev txuag nqi

• Single-setup machiningtxo lub sij hawm ntau lawm los ntawm 40-60% piv rau ntau theem txheej txheem. Rau qhov project satellite optical vaj tsev, peb txiav lub sij hawm txhuas los ntawm 14 hnub mus rau 6.

• Automated toolpaths txo cov khoom pov tseg-tseem ceeb rau cov khoom kim heev xws li fused silica lossis Zerodur® .

Peb lub Hoobkas muaj peev xwm tshwj xeeb

1. Advanced Multi-Axis Khoom

- 5-Axis CNC Centers: DMU 65 monoBLOCK® (mus ncig: X-1400mm, Y-900mm, Z-700mm; spindle: 42,000 RPM) rau kev kub ceev, tsis muaj kev vibration.

- Ultra-Precision Add-ons: Integrated laser probes rau real-time metrology thiab adaptive toolpath kho thaum machining.

- In-Process Monitoring: Txhua yam khoom muaj peb qhov chaw kuaj xyuas:

2. Kev Tswj Xyuas Zoo Zoo

Raw khoom spectrometry (ISO 17025-certified lab).

On-machine probing rau qhov tseeb qhov tseeb.

Tom qab txheej txheem CMM validation (Zeiss CONTURA G2, qhov tseeb: 1.1µm + L / 350µm).

•ISO 9001/13485 Kev Ua Raws Cai: Documented workflows kom traceability los ntawm kev tsim mus rau kev xa khoom.

3. Ntau yam khoom siv & kev paub siv

Khoom siv: Optical iav, ceramics, titanium, Inconel®.

Daim ntawv thov: Endoscopes, VR lens arrays, fiber ntau optic collimators, aerospace reflectors.

4. Xaus-rau-End Customer Support

•Tsim kev sib koom tes: Peb cov engineers optimize designs for manufacturability (DFM)—xws li, simplifying undercuts kom txo tau cov nqi.

•Tom qab-Delivery Assurance:

o24/7 technical hotline (<30-min teb).

oKev pab txhawb nqa lub neej + 2 xyoo warranty.

oSpare-part logistics: Kev xa khoom thoob ntiaj teb hauv 72 teev.

Case Study: High-NA Microscope Objective Lens

Kev sib tw: Ib tus neeg siv tshuaj biomedical xav tau 200 lo ntsiab muag nrog micro-grooves (qhov tob: 50µm ± 2µm) rau fluidic light-guiding.

Kev daws:

•Peb 5-axis CNC programmed elliptical toolpaths nrog lub kaum ntse ntse sib txawv.

•Nyob rau hauv-txoj kev laser scanning pom deviations> 1µm, ua rau nws pib kho.

Kev tshwm sim: 0% tsis lees txais tus nqi; 98% raws sij hawm xa tuaj.

FAQs: Hais txog cov neeg siv khoom tseem ceeb txhawj xeeb

Q: Koj puas tuaj yeem ua cov duab geometry nrog undercuts lossis tsis sib hloov symmetry?

A: Yog lawm. Peb 5-axis CNC lub tilt-rotary ntxhuav nkag cov ces kaum mus txog 110 °, machining nta zoo li helical channels los yog off-axis parabolic nto yam tsis muaj refixturing.

Q: Koj ua li cas kom ntseeg tau qhov muag pom kev ncaj ncees?

A: Peb siv cov cuab yeej pob zeb diamond-coated nrog nano-polishing cycles, ua tiav qhov roughness (Ra) <10nm - tseem ceeb rau kev siv laser.

Q: Yuav ua li cas yog tias kuv xav tau kev hloov kho tom qab tsim khoom?

A: Peb lub vev xaib huab cua tso cai rau koj xa cov kev hloov kho, nrog cov qauv tshiab xa tuaj hauv 5-7 hnub.

Q: Dab tsi'koj lub lag luam twg?

A: OEM Service. Peb qhov kev lag luam yog CNC tshuab dhos ua tiav, tig, stamping, thiab lwm yam.

Q. Yuav tiv tauj peb li cas?

A: Koj tuaj yeem xa cov lus nug ntawm peb cov khoom, nws yuav teb rau hauv 6 teev; Thiab koj tuaj yeem tiv tauj nrog peb ncaj qha los ntawm TM lossis WhatsApp, Skype raws li koj nyiam.

Q.Dab tsi kuv yuav tsum tau muab rau koj rau kev nug?

A: Yog tias koj muaj cov duab kos lossis cov qauv, pls xav tias dawb xa tuaj rau peb, thiab qhia rau peb koj cov kev xav tau tshwj xeeb xws li cov khoom siv, kev ua siab ntev, kev kho deg thiab tus nqi koj xav tau, ect.

Q.Dab tsi txog hnub xa khoom?

A: Hnub xa khoom yog li 10-15 hnub tom qab tau txais cov nyiaj them poob haujlwm.

Q.Dab tsi txog cov nqe lus them nqi?

A: Feem ntau EXW LOSSIS FOB Shenzhen 100% T / T ua ntej, thiab peb tuaj yeem sab laj rau koj qhov kev xav tau.