Hnub no's ceev-pacedkev tsim khoom lub ntiaj teb no, cov lag luam thoob plaws ntau yam industries yog nce nyob rau hauv kev cai machining kom tau raws li qhov kev thov nce rau precision-engineered Cheebtsam. Raws li kev lag luam evolve thiab cov khoom tsim los ua complex, lub peev xwm los tsim cov kev cai qhov chaw nrog cov specifications exacting yeej tsis tau tseem ceeb tshaj. Kev cai machining muaj ntau yam, muaj txiaj ntsig zoo, thiab kev daws teeb meem zoo rau cov tuam txhab nrhiav cov khoom lag luam zoo, txiav cov khoom uas haum rau lawv cov kev xav tau tshwj xeeb.

Los ntawm aerospace mus rau cov cuab yeej kho mob, tsheb mus rau hluav taws xob, qhov kev thov rau cov khoom siv ua haujlwm tau nce siab. Kab lus no tshawb txog qhov kev cai machining yog vim li cas, vim li cas nws thiaj li tau txais traction thoob plaws kev lag luam, cov txiaj ntsig nws muaj, thiab nws hloov pauv li cas ntawm kev tsim khoom.

Custom Machining yog dab tsi?

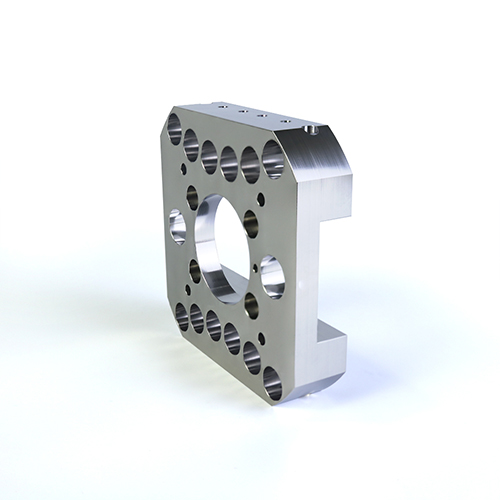

Kev cai machining yog hais txog cov txheej txheem tsim khoom uas cov khoom ua haujlwm (feem ntau yog ua los ntawm cov hlau, yas, lossis cov khoom sib xyaw) yog zoo li tus, txiav, lossis ua tiav kom tau raws li qhov tshwj xeeb thiab qhov ntev. Tsis zoo li cov tsoos, cov khoom tsim tawm ntau, kev siv lub tshuab ua kom haum raws li tus neeg siv khoom xav tau, tso cai rau cov geometries intricate, nruj tolerances, thiab high-quality finishes.

Siv technologies xws liCNC(Computer Numerical Control) machining, milling, tig, sib tsoo, thiab drilling, kev cai machining tuaj yeemtsim qhov chawntawm ntau yam complexities - los ntawm tej yam yooj yim, haumxeeb pieces mus intricate, high-precision Cheebtsam rau industries xws li aerospace, automotive, kev kho mob, thiab ntau dua.

Vim li cas Custom Machining thiaj li tau txais kev nyiam

Ntau yam tau ua rau muaj kev vam khom rau kev ua haujlwm ntawm kev ua haujlwm thoob plaws kev lag luam. Cov no suav nrog:

●Ua kom yooj yim hauv kev tsim:Raws li kev lag luam thawb cov ciam teb ntawm kev tsim kho tshiab, cov khoom tsim tau dhau los ua qhov nyuaj. Kev cai machining tso cai rau cov tuam txhab tsim cov khoom uas ua tau raws li cov lus qhia tshwj xeeb, muab qhov yooj yim los tsim cov khoom nrog cov duab nyuaj, nkhaus, thiab cov ncauj lus kom ntxaws uas yuav nyuaj lossis tsis tuaj yeem ua tiav los ntawm cov txheej txheem tsim khoom ib txwm muaj.

● Khoom siv ntau yam:Kev cai machining yog tsim rau ntau yam ntaub ntawv, xws li hlau (xws li txhuas, stainless hlau, thiab titanium) rau yas (xws li polycarbonate thiab nylon) thiab composites. Qhov kev ua tau zoo no tso cai rau cov tuam txhab xaiv cov khoom siv zoo tshaj plaws rau lawv daim ntawv thov tshwj xeeb, txawm tias lawv xav tau lub teeb yuag, ruaj khov, lossis cov khoom tiv thaiv corrosion.

● High Precision thiab Tolerances:Ib qho ntawm qhov zoo tshaj plaws ntawm kev cai machining yog qhov muaj peev xwm ua tiav qhov kev ua siab ntev (raws li meej li ± 0.001 ntiv tes lossis tsawg dua). Hauv kev lag luam xws li cov cuab yeej kho mob, aerospace, thiab electronics, precision yog qhov tseem ceeb. Kev cai machining ua kom ntseeg tau tias txhua feem haum zoo kawg nkaus thiab ua haujlwm tau zoo, txawm tias nyob rau hauv kev siv lub luag haujlwm tseem ceeb.

● Kev Tsim Nyog Nqi Tsawg:Thaum cov txheej txheem tsim khoom siab xws li kev txhaj tshuaj molding lossis tuag-casting feem ntau xav tau cov cuab yeej kim thiab pwm, kev cai machining tuaj yeem raug nqi rau qis mus rau nruab nrab ntau lawm. Txij li nws tsis xav tau kev tsim cov cuab yeej tshwj xeeb, cov nqi cuam tshuam nrog kev cai machining feem ntau qis dua, tshwj xeeb tshaj yog rau prototyping lossis me me batch ntau lawm.

● Rapid Prototyping thiab Iteration:Kev cai machining yog qhov kev daws teeb meem zoo tshaj plaws rau kev tsim qauv sai. Cov kws tshaj lij tuaj yeem tsim qauv qauv sai sai, sim nws, thiab rov ua dua ntawm tus qauv tsim yam tsis muaj kev ncua lossis nqi. Qhov no agility accelerates txoj kev loj hlob thiab txo lub sij hawm-rau-kev ua lag luam rau cov khoom tshiab.

Kev Cai Machining Ua Haujlwm Li Cas?

Cov txheej txheem machining kev cai suav nrog ntau cov kauj ruam tseem ceeb, txhua lub hom phiaj kom ntseeg tau tias qhov kawg ua tau raws li cov lus qhia meej uas tau teev tseg los ntawm tus neeg siv khoom:

● Tsim Phase:Thawj kauj ruam hauv kev cai machining yog kev tsim cov qauv tsim. Qhov no feem ntau ua tiav siv CAD (Computer-Aided Design) software, uas tso cai rau cov engineers thiab cov tsim qauv tsim 2D lossis 3D qauv ntawm ib feem. Tus tsim CAD yog tom qab ntawd hloov mus rau hauv lub tshuab nyeem tau, feem ntau hauv daim ntawv G-code.

● Xaiv cov khoom siv:Raws li ib feem ntawm txoj haujlwm thiab cov kev cai tshwj xeeb ntawm qhov project, cov khoom tsim nyog raug xaiv. Cov ntaub ntawv muaj xws li hlau xws li stainless hlau, txhuas, titanium, thiab tooj dag, nrog rau engineering yas xws li Delrin, Nylon, thiab PTFE. Cov ntaub ntawv uas muaj cov yam ntxwv tshwj xeeb xws li kub tsis kam, conductivity, lossis corrosion kuj raug xaiv raws li daim ntawv thov.

● Machining Txheej Txheem:Siv lub tshuab CNC, cov khoom siv tau raug txiav, zoo li tus, thiab tiav. Lub tshuab CNC ua raws li G-code cov lus qhia kom ua tiav ntau yam haujlwm, suav nrog milling, tig, drilling, lossis sib tsoo. Lub tshuab yuav muaj ntau lub axes ntawm cov lus tsa suab (feem ntau 3, 4, lossis 5 axes) kom tso cai rau kev ua haujlwm nyuaj, ntau qhov kev txiav thiab shaping.

● Tom qab ua tiav:Tom qab cov txheej txheem machining, yuav tsum tau ua kom tiav cov kauj ruam ntxiv, xws li deburring (tshem tawm cov npoo ntse), polishing, lossis txheej. Cov kauj ruam tom qab ua tiav no pab ua tiav qhov xav tau ntawm qhov chaw tiav thiab txhim kho qhov zoo li thiab ua haujlwm.

● Kev Tswj Xyuas Zoo:Kev tswj kom zoo yog ib qho tseem ceeb ntawm cov kev cai machining. Cov khoom raug tshuaj xyuas kom ntseeg tau tias lawv ua tau raws li qhov xav tau tshwj xeeb thiab kev zam. Qhov no tuaj yeem suav nrog kev tshuaj xyuas qhov muag, ntsuas qhov ntev siv cov cuab yeej xws li CMM (Kev Sib Koom Tes Ntsuas Cov Tshuab), thiab ntsuas lub zog, ua haujlwm ntev, thiab lwm yam khoom siv.

● Kev xa khoom:Thaum ib feem dhau qhov kev tswj xyuas zoo, nws npaj txhij rau kev xa mus rau cov neeg siv khoom. Kev hloov pauv sai thiab hloov pauv ntawm kev cai machining kom ntseeg tau tias cov tuam ntxhab tuaj yeem ua tau raws li cov sijhawm tsim khoom nruj.

Cov txiaj ntsig tseem ceeb ntawm Custom Machining

Kev cai machining muaj ntau qhov zoo, ua rau nws yog qhov kev xaiv zoo rau cov lag luam tab tom nrhiav los tsim cov khoom zoo, precision-engineered Cheebtsam.

● Kev yooj yim hauv kev tsim thiab tsim khoom:Kev cai machining tuaj yeem tswj tau ntau yam qauv tsim thiab cov ntaub ntawv, ua rau nws yooj yim heev rau kev tsim khoom. Txawm hais tias koj xav tau ib qho yooj yim los yog ib qho nyuaj heev, muaj ntau yam tshwj xeeb, kev siv tshuab tuaj yeem ua raws li koj xav tau.

● Precision thiab raug:CNC machining muab qhov tsis sib haum xeeb, ua rau nws zoo tagnrho rau cov ntawv thov uas txhua feem ntawm ib millimeter suav. Cov khoom tsim los ntawm kev cai machining tuaj yeem ua tau raws li qhov nruj raws li ± 0.001 ntiv tes, kom ntseeg tau tias cov khoom kawg haum zoo kawg nkaus thiab ua haujlwm raws li qhov xav tau.

● Nqi-zoo rau kev khiav qis qis:Rau kev lag luam uas xav tau cov khoom me me lossis cov khoom siv kev cai, kev cai machining tuaj yeem yog cov tshuaj siv nyiaj ntau dua li kev tsim khoom ib txwm muaj. Qhov tsis muaj cov cuab yeej ua ntej thiab muaj peev xwm kho tau sai sai rau kev hloov pauv lossis hloov kho tshiab ua rau nws yog qhov kev daws teeb meem zoo tshaj plaws rau kev ua haujlwm qis mus rau nruab nrab.

● High-Quality Surface Finishes:Kev cai machining tuaj yeem ua tiav qhov zoo tshaj plaws ntawm qhov kawg, uas yog qhov tseem ceeb rau ob qho tib si zoo li thiab kev ua haujlwm ntawm qhov chaw. Cov kauj ruam tom qab ua tiav zoo li polishing, txheej, thiab anodizing tuaj yeem siv los txhim kho cov khoom nto ntawm qhov chaw, ua kom lawv ua tau raws li qhov xav tau ntawm kev zoo nkauj thiab kev ua haujlwm.

● Kev hloov pauv sai:Kev muaj peev xwm sai sai tsim cov qauv lossis cov khoom npaj ua ntej ua rau kev cai machining ib qho kev xaiv mus rau cov lag luam uas xav tau txo lub sij hawm-rau-kev ua lag luam. Thaum tus tsim tiav lawm, CNC tshuab tuaj yeem pib tsim cov khoom yuav luag tam sim ntawd, ua rau lub voj voog loj hlob sai.

Kev lag luam uas tau txais txiaj ntsig los ntawm Custom Machining

● Aerospace:Kev cai machining yog qhov tseem ceeb hauv kev tsim khoom hauv aerospace, qhov chaw yuav tsum ua raws li cov qauv kev nyab xeeb thiab kev ua tau zoo. Lub cav Cheebtsam, brackets, tsaws iav qhov chaw, thiab turbine hniav yog feem ntau custom-machined kom tau raws li qhov xav tau ntawm kev lag luam aerospace.

● Cov Khoom Siv Kho Mob:Hauv kev kho mob, kev siv lub tshuab yog siv los tsim cov khoom xws li cov cuab yeej phais, kev cog hniav, thiab cov khoom siv tes ua. Cov khoom no yuav tsum muaj kev ua haujlwm siab thiab yuav tsum feem ntau yog biocompatible lossis tiv taus corrosion thiab hnav.

● Automotive:Kev cai machining yog siv los tsim cov khoom tseem ceeb hauv tsheb xws li cav qhov chaw, nres, cov khoom raug tshem tawm, thiab cov khoom sab hauv. Machining tso cai rau siab precision thiab durability, uas yog ib qho tseem ceeb rau lub tsheb kev nyab xeeb thiab kev ua tau zoo.

● Electronics:Kev lag luam hluav taws xob tso siab rau kev cai machining rau cov khoom xws li enclosures, connectors, thiab heat sinks. Cov khoom no tseem ceeb heev rau kev tiv thaiv cov khoom siv hluav taws xob rhiab heev thiab ua kom ntseeg tau tias kev ua tau zoo.

● Cov Khoom Siv Muaj:Kev cai machining yog siv nyob rau hauv manufacturing complex qhov chaw rau machinery thiab industrial khoom. Seb nws yog tsim cov iav, ncej, los yog hydraulic Cheebtsam, kev cai machining muaj cov precision thiab durability uas yuav tsum tau rau kev lag luam daim ntaub ntawv.

Lub neej yav tom ntej ntawm Custom Machining

Lub neej yav tom ntej ntawm kev cai machining yog ci ntsa iab, nrog kev nce qib hauv kev siv thev naus laus zis txuas ntxiv tsav kev lag luam mus tom ntej. Automation, AI kev koom ua ke, thiab cov khoom siv siab heev yuav tsum ua lub luag haujlwm tseem ceeb hauv kev txhim kho precision, efficiency, thiab sustainability.

● AI thiab Automation:Kev koom ua ke ntawm AI thiab tshuab kev kawm rau hauv CNC machining cov txheej txheem yuav tsum txhim kho lub peev xwm ntawm cov tshuab kom hloov kho thiab ua kom zoo rau kev ua haujlwm hauv lub sijhawm, ntxiv txhim kho kev ua haujlwm thiab txo qis sijhawm.

● Additive Manufacturing Integration:Kev sib xyaw ua ke ntawm 3D luam ntawv (kev tsim khoom ntxiv) thiab kev ua haujlwm kev cai twb tau hloov pauv kev lag luam los ntawm kev muab cov qauv tsim kom yooj yim dua. Hybrid manufacturing txheej txheem uas muab ob qho tib si machining thiab 3D luam ntawv tau dhau los ua ntau dua.

● Sustainability:Raws li kev ruaj ntseg dhau los ua qhov tseem ceeb hauv kev lag luam, kev ua haujlwm kev cai yuav txuas ntxiv mus ntxiv nrog rau qhov tseem ceeb ntawm kev txo cov khoom pov tseg thiab siv cov khoom siv rov ua dua lossis cov khoom siv hauv eco.

Post lub sij hawm: Jun-09-2025