Sib Nqus vs Pneumatic Ua Haujlwm rau Nyias Sheet Aluminium

Sau: PFT, Shenzhen

Abstract

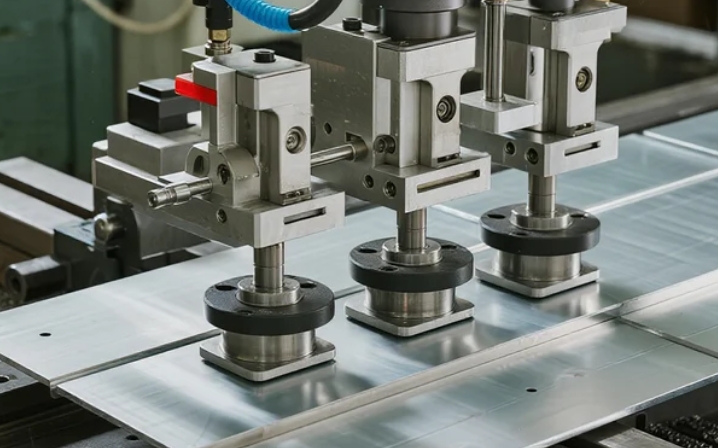

Precision machining ntawm nyias daim ntawv txhuas (<3mm) ntsib teeb meem ua haujlwm tseem ceeb. Txoj kev tshawb no piv cov hlau nplaum thiab pneumatic clamping tshuab nyob rau hauv kev tswj CNC milling tej yam kev mob. Kev ntsuas ntsuas suav nrog clamping quab yuam sib xws, thermal stability (20 ° C-80 ° C), kev co damping, thiab deformtion deg. Pneumatic lub tshuab nqus tsev chucks khaws cia 0.02mm flatness rau 0.8mm nplooj ntawv tab sis yuav tsum tau ua kom zoo sealing nto. Electromagnetic chucks enabled 5-axis nkag thiab txo lub sij hawm teem los ntawm 60%, tsis tau induced eddy tam sim no ua rau lub zos cua sov tshaj 45 ° C ntawm 15,000 RPM. Cov txiaj ntsig tau qhia tias lub tshuab nqus tsev ua kom zoo dua qhov ua tiav rau cov ntawv> 0.5mm, thaum cov kev daws teeb meem sib nqus txhim kho qhov yooj yim rau kev tsim qauv sai. Cov kev txwv muaj xws li cov kev tsis sib haum xeeb uas tsis muaj kev sib tw thiab lwm txoj hauv kev nplaum.

1 Kev Taw Qhia

Nyias aluminium nplooj ntawv fais fab kev lag luam los ntawm aerospace (fuselage skins) mus rau electronics (heat sink fabrication). Txawm li cas los xij 2025 kev tshawb fawb kev lag luam qhia 42% ntawm qhov tsis xws luag yog los ntawm kev txav mus los ntawm kev ua haujlwm thaum lub sijhawm ua haujlwm. Cov cuab yeej siv tshuab clamps feem ntau cuam tshuam cov nplooj ntawv sub-1mm, thaum txoj kev siv daim kab xev tsis muaj rigidity. Txoj kev tshawb no suav txog ob txoj kev daws teeb meem: electromagnetic chucks leveraging remanence control technology thiab pneumatic systems with multi-zone vacuum control.

2 Txoj kev

2.1 Kev sim tsim qauv

-

Khoom siv: 6061-T6 txhuas ntawv (0.5mm / 0.8mm / 1.2mm)

-

Khoom siv:

-

Sib nqusGROB 4-axis electromagnetic chuck (0.8T teb siv)

-

Pneumatic: SCHUNK lub tshuab nqus tsev phaj nrog 36-zone manifold

-

-

Kev ntsuam xyuas: Nto flatness (laser interferometer), thermal imaging (FLIR T540), kev vibration tsom xam (3-axis accelerometers)

2.2 Test Protocols

-

Static Stability: Ntsuas deflection nyob rau hauv 5N lateral quab yuam

-

Thermal Cycling: Cov ntaub ntawv kub gradients thaum lub sij hawm milling (Ø6mm kawg zeb, 12,000 RPM)

-

Dynamic Rigidity: Quantify vibration amplitude ntawm resonant zaus (500-3000 Hz)

3 Kev Tshawb Fawb thiab Kev Tshawb Fawb

3.1 Clamping Performance

| Parameter | Pneumatic (0.8 hli) | Sib nqus (0.8mm) |

|---|---|---|

| Avg. Distortion | 0.02 hli | 0.15 hli |

| Teem sijhawm | 8,5 nqi | 3.2 min |

| Max Temp Rise | 22°C kub | 48 ° C |

Daim duab 1: Lub tshuab nqus tsev khaws cia <5μm nto variation thaum lub ntsej muag milling, qhov sib nqus clamping pom 0.12mm ntug nqa vim thermal expansion.

3.2 Cov yam ntxwv vibration

Pneumatic chucks attenuated harmonics los ntawm 15dB ntawm 2,200Hz - qhov tseem ceeb rau kev ua tiav zoo. Magnetic workholding nthuav tawm 40% siab dua amplitude ntawm cov cuab yeej koom nrog zaus.

4 Kev sib tham

4.1 Technology Tradeoffs

-

Pneumatic Advantage: Superior thermal stability thiab vibration damping suit high-tolerance applications xws li optical component bases.

-

Sib Nqus Ntug: Kev teeb tsa nrawm nrawm txhawb kev ua haujlwm hauv khw ib puag ncig tuav ntau qhov ntau thiab tsawg.

Kev txwv: Kev ntsuam xyuas tsis suav nrog cov nplooj ntawv perforated lossis oily uas lub tshuab nqus tsev vacuum poob> 70%. Cov kev daws teeb meem hybrid lav kev kawm yav tom ntej.

5 Kev xaus

Rau nyias aluminium ntawv machining:

-

Pneumatic workholding muab siab dua precision rau thicknesses> 0.5mm nrog uncompromised nto

-

Cov tshuab hlau nplaum txo cov sij hawm tsis txiav los ntawm 60% tab sis xav tau cov tswv yim txias rau kev tswj xyuas thermal

-

Kev xaiv zoo nyob ntawm qhov kev xav tau dhau los piv rau qhov yuav tsum tau ua siab ntev

Kev tshawb fawb yav tom ntej yuav tsum tshawb nrhiav kev hloov pauv hybrid clamps thiab cov qauv tsim hluav taws xob tsis zoo.

Post lub sij hawm: Lub Xya hli ntuj-24-2025