Raws li kev lag luam thoob ntiaj teb xav tau cov khoom lag luam uas yog ob qho tib si muaj tseeb thiab ua tau sai,manufacturers tab tom tig mus rau cov kev daws teeb meem siab heev los tswj kev sib tw. Los ntawm 2025, CNC tig tau hloov zuj zus los ntawm cov txheej txheem tshwj xeeb mus rau lub hauv paus tsim cov tswv yim, ua kom cov khoom ntawm cov complex, siab kam rau ua qhov chaw nrog lub sij hawm luv luv thiab yooj yim dua. Qhov kev hloov pauv no tshwj xeeb yog tshwm sim hauv cov haujlwm xws li kev tsim tsheb hluav taws xob, kev tsim khoom siv phais mob, thiab kev sib txuas lus hauv kev sib txuas lus, qhov chaw zoo thiab kev tsim khoom muaj zog yog qhov tseem ceeb.

CNC tig yog dab tsi?

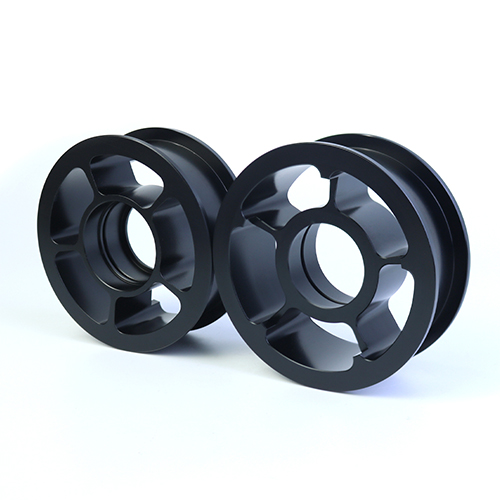

CNC tig yog cov txheej txheem tsim tawm uas lub tshuab dhos lub computer tswj tau tig lub tshuab ua haujlwm thaum lub cuab yeej txiav nws ua rau hauv daim ntawv xav tau. Nws feem ntau yog siv rau cylindrical lossis puag ncig, tab sis cov tshuab niaj hnub no tso cai rau cov geometries nyuaj nrog ntau lub peev xwm.

Cov txheej txheem tuaj yeem lis ntau yam khoom siv, suav nrog:

● Stainless hlau

● Aluminium

● tooj dag

● Titanium

● Cov yas thiab cov khoom sib xyaw

CNC tig cov kev pabcuam feem ntau yog siv los tsim cov khoom xws li:

● Ncej thiab pins

● Bushings thiab bearings

● Nozzles thiab connectors

● Lub tsev thiab lub tes tsho

Cov txiaj ntsig thiab Kev Ntsuam Xyuas

1. Precision thiab nto zoo

CNC tig nrog adaptive toolpaths thiab cov cuab yeej nyob tsis tu ncua nyob rau hauv siab nyob rau hauv ± 0.005 hli thiab tiav nto roughness qhov tseem ceeb ntawm Ra 0.4-0.8 μm.

2. Ntau lawm Ceev thiab Flexibility

Kev sib koom ua ke ntawm cov khoom siv hluav taws xob pallet hloov pauv thiab cov neeg hlau ua haujlwm txo qis lub sijhawm nruab nrab ntawm lub voj voog los ntawm 35-40% thiab tso cai hloov pauv sai ntawm cov khoom siv ntau lawm.

3. Scalability thiab nqi zog

High-volume ntau lawm khiav tau pom nyob ze-linear scalability tsis poob ntawm precision, thaum me me batches tau txais txiaj ntsig los ntawm kev txo lub sij hawm teeb tsa thiab kev cuam tshuam me me.

Kev sib tham

1. Kev txhais cov txiaj ntsig

Lub precision thiab ceev qhov zoo ntawm niaj hnub CNC tig yog feem ntau yog vim li cas rau kev nce qib hauv tshuab rigidity, spindle tsim, thiab kaw-voj tawm tswv yim systems. Scalability yog txhim kho los ntawm kev koom ua ke nrog kev tsim cov tshuab ua haujlwm (MES) thiab IoT-enabled tshuab xyuas.

2. Cov kev txwv

Txoj kev tshawb no tsom rau kev hloov chaw los ntawm peb lub tuam txhab; kev ua tau zoo yuav txawv nrog lub hnub nyoog ntawm lub tshuab, hom tswj, thiab cov cuab yeej siv nyiaj txiag. Kev lag luam xws li kev siv hluav taws xob thiab kev nqis peev thawj zaug tsis yog lub hauv paus rau qhov kev tshuaj ntsuam no.

3. Kev cuam tshuam

CNC tig yog tshwj xeeb tshaj yog haum rau cov tuam txhab nrhiav kom muab cov khoom zoo nrog cov lus teb sai rau kev hloov pauv hauv kev lag luam. Kev lag luam uas xav tau cov geometries nyuaj-xws li hydraulics, optics, thiab kev tiv thaiv- tuaj yeem tau txais txiaj ntsig zoo los ntawm kev siv lossis nthuav dav txoj hauv kev.

Kev lag luam tseem ceeb tsav kev loj hlob

●Aerospace:High-performance shafts, fasteners, thiab vaj tse yuav tsum tau heev precision thiab cov khoom ncaj ncees.

● Automotive:CNC-tig Cheebtsam yog pom nyob rau hauv lub ncua kev kawm ntawv systems, gear assemblies, thiab engine qhov chaw.

●Cov cuab yeej kho mob:Cov cuab yeej phais, kev cog qoob loo, thiab cov khoom sib txuas tau txais txiaj ntsig los ntawm kev nthuav dav zoo thiab cov khoom siv sib xws CNC tig muab.

●Roj & Roj:Cov khoom siv ruaj khov xws li flanges, li qub, thiab cov casings nyob ntawm lub zog thiab qhov tseeb ntawm CNC tig.

●Cov khoom siv:Txawm tias cov khoom kim heev-xws li watches thiab cwj mem-leverage CNC-tig qhov chaw rau durability thiab pom kev rov hais dua.

Kev xav zaum kawg

Txawm hais tias koj tab tom nthuav tawm cov khoom lag luam tshiab lossis hloov kho koj cov khoom siv, CNC tig cov kev pabcuam muab txoj hauv kev ua pov thawj rau kev tsim khoom sai dua, zoo dua, thiab kev loj hlob tuaj yeem.

Raws li kev lag luam hloov mus rau precision-tsav manufacturing, CNC tig yog ntau tshaj li ib tug machining txoj kev - nws yog ib tug kev sib tw kom zoo dua.

Post lub sij hawm: Aug-27-2025