PFT, Shenzhen

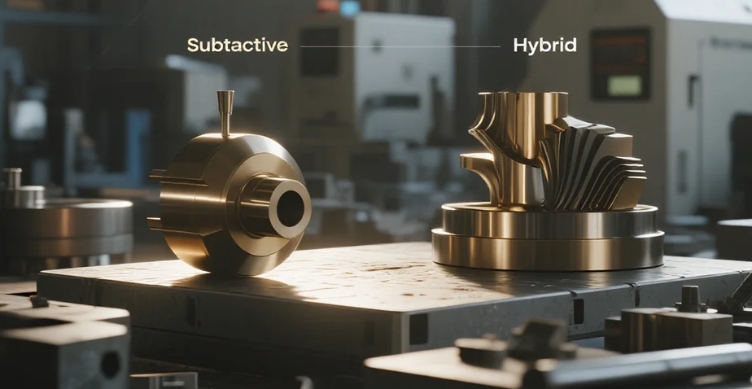

Txoj kev tshawb no piv cov kev ua tau zoo ntawm cov tsoos subtractive CNC machining nrog tawm hybrid CNC-Additive Manufacturing (AM) rau kev kho cov cuab yeej. Kev ntsuas kev ua tau zoo (lub sijhawm kho, siv cov khoom siv, lub zog siv tshuab) tau suav nrog siv cov kev sim tswj ntawm kev puas ntsoog tuag. Cov txiaj ntsig qhia tau hais tias hybrid txoj kev txo cov khoom pov tseg los ntawm 28-42% thiab txo qis kev kho lub voj voog los ntawm 15-30% piv rau cov kev rho tawm nkaus xwb. Microstructural tsom xam pom tias muaj zog tensile piv (≥98% ntawm cov cuab yeej qub) hauv hybrid-repaired Cheebtsam. Qhov kev txwv tseem ceeb suav nrog geometric complexity txwv rau AM deposition. Cov kev tshawb pom no qhia tau hais tias hybrid CNC-AM raws li lub tswv yim siv tau rau kev saib xyuas cov cuab yeej ruaj khov.

1 Kev Taw Qhia

Cov cuab yeej degradation raug nqi tsim khoom lag luam $ 240B ib xyoos ib zaug (NIST, 2024). Kev kho cov txheej txheem CNC tshem tawm cov khoom puas los ntawm kev sib tsoo / sib tsoo, feem ntau muab pov tseg> 60% ntawm cov khoom khaws cia. Hybrid CNC-AM kev koom ua ke (kev siv hluav taws xob ncaj qha mus rau cov cuab yeej uas twb muaj lawm) cog lus tias muaj peev xwm ua tau zoo tab sis tsis muaj kev siv tau zoo. Qhov kev tshawb fawb no suav cov txiaj ntsig ntawm kev ua haujlwm zoo ntawm kev ua haujlwm hybrid piv rau cov qauv kev rho tawm rau cov cuab yeej muaj txiaj ntsig zoo.

2 Txoj kev

2.1 Kev sim tsim qauv

Tsib puas lawm H13 steel stamping tuag (qhov loj me: 300 × 150 × 80mm) underwent ob txoj kev kho:

-

Pawg A (Subtractive):

- Kev puas tsuaj tshem tawm ntawm 5-axis milling (DMG MORI DMU 80)

- Welding filler deposition (GTAW)

- Ua tiav machining rau thawj CAD -

Pawg B (Hybrid):

- Tshem tawm qhov tsis xws luag (<1mm qhov tob)

- DED kho siv Meltio M450 (316L hlau)

- Adaptive CNC remachining (Siemens NX CAM)

2.2 Kev Tau Txais Cov Ntaub Ntawv

-

Cov Khoom Siv Ua Haujlwm: Kev ntsuas loj ua ntej / tom qab kho (Mettler XS205)

-

Lub Sijhawm Taug Kev: Cov txheej txheem saib xyuas nrog IoT sensors (ToolConnect)

-

Mechanical Testing:

- Daim ntawv qhia Hardness (Buehler IndentaMet 1100)

- Cov qauv Tensile (ASTM E8 / E8M) los ntawm thaj chaw kho

3 Cov txiaj ntsig & Kev Ntsuam Xyuas

3.1 Kev siv peev txheej

Table 1: Kho Txheej Txheem Metrics Sib Piv

| Metric | Kev Kho Kom Zoo | Hybrid Kho | Kev txo qis |

|---|---|---|---|

| Khoom siv | 1,850g ± 120g | 1,080g ± 90g | 41.6% |

| Active Kho Sijhawm | 14.2 teev ± 1.1 teev | 10.1 teev ± 0.8 teev | 28.9% |

| Kev siv zog | 38.7 kWh ± 2.4 kWh | 29.5 kWh ± 1.9 kWh | 23.8% |

3.2 Mechanical Integrity

Hybrid-repaired specimens nthuav tawm:

-

Ua kom tawv tawv (52–54 HRC vs. thawj 53 HRC)

-

Lub zog tensile kawg: 1,890 MPa (± 25 MPa) - 98.4% ntawm cov khoom siv hauv paus

-

Tsis muaj interfacial delamination hauv kev sim qaug zog (10⁶ cycles ntawm 80% yield stress)

Daim duab 1: Microstructure ntawm hybrid kho interface (SEM 500 ×)

Nco tseg: Equiaxed grain qauv ntawm fusion ciam teb qhia tau zoo thermal tswj.

4 Kev sib tham

4.1 Kev ua haujlwm cuam tshuam

Lub sijhawm txo 28.9% yog los ntawm kev tshem tawm cov khoom tshem tawm ntau. Hybrid processing proves zoo rau:

-

Cov cuab yeej qub txeeg qub teg nrog cov khoom siv tsis tu ncua

-

High-complexity geometries (piv txwv li, conformal cua txias channel)

-

Tsawg-volume kho scenarios

4.2 Technical Constraints

Cov kev txwv tau pom:

-

Lub kaum sab xis siab tshaj plaws: 45 ° los ntawm kab rov tav (tiv thaiv overhang defects)

-

DED txheej thickness variance: ± 0.12mm yuav tsum tau adaptive toolpaths

-

Tom qab txheej txheem HIP kev kho mob tseem ceeb rau aerospace-qib cov cuab yeej

5 Kev xaus

Hybrid CNC-AM txo cov cuab yeej kho cov cuab yeej siv los ntawm 23-42% thaum tswj kev sib npaug ntawm cov cuab yeej siv rau kev rho tawm. Kev nqis tes ua yog pom zoo rau cov khoom uas muaj qhov tsis sib xws ntawm cov duab geometric uas cov khoom khaws cia ua pov thawj rau AM cov nqi ua haujlwm. Kev tshawb fawb tom ntej yuav ua kom zoo dua cov tswv yim tso nyiaj rau cov cuab yeej tawv tawv (> 60 HRC).

Post lub sij hawm: Aug-04-2025