Los ntawm kev ruaj ntseg qhov rooj xauv rau du-rolling skateboards,precision machined qhov chawua lub luag haujlwm feem ntau tsis pom zoo hauv cov khoom lag luam thiab kev paub txog cov neeg siv khoom. Kev ua lag luam thoob ntiaj teb rau cov khoom lag luam zoo li no tau tshaj $ 12 nphom hauv 2024, tau tsav los ntawm kev thov kom muaj kev ntseeg siab dua thiab kev hloov kho (Global Machining Report, 2025). Daim ntawv no txheeb xyuas li casniaj hnub machining cov txheej txheempab kom txoj kev geometries thiab nruj tolerances nyob rau hauv ntau haiv neeg daim ntawv thov, kev txhim kho ob qho tib si muaj nuj nqi thiab durability.

Txoj kev

1. Kev Tshawb Fawb Tsim

Cov txheej txheem multi-tiered tau ua haujlwm:

● Laboratory kuaj ntawm machined vs. non-machined Cheebtsam nyob rau hauv simulated siv tej yam kev mob

● Kev tshuaj xyuas cov ntaub ntawv tsim khoom los ntawm 8 tus neeg koom tes tsim khoom

● Cov ntaub ntawv tshawb fawb hla kev lag luam hauv kev tsim kho, tsheb, thiab cov khoom ua si

2.Technical Approach

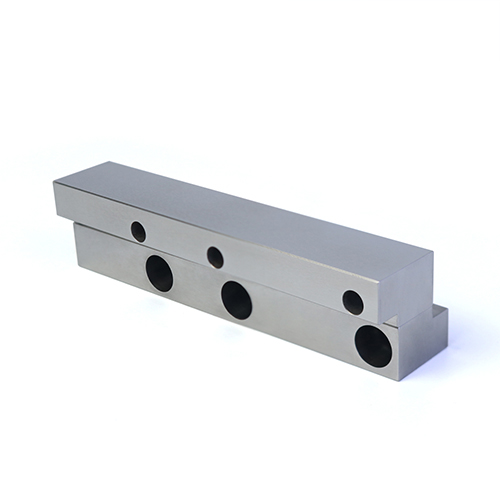

●Cov txheej txheem Machining:5-axis CNC milling (Haas UMC-750) thiab Swiss-hom tig (Citizen L20)

●Khoom siv:Aluminium 6061, stainless hlau 304, thiab tooj dag C360

●Cov cuab yeej tshuaj xyuas:Zeiss CONTURA CMM thiab Keyence VR-5000 optical comparator

3. Kev ntsuas kev ua tau zoo

● Kev qaug zog lub neej (kev sim ntsuas ib puag ncig ASTM E466)

● Dimensional raug (ISO 2768-1 zoo kam rau ua)

● Teb tsis ua hauj lwm tus nqi los ntawm cov neeg siv khoom rov qab los

Cov txiaj ntsig thiab Kev Ntsuam Xyuas

1.Kev ua tau zoo

CNC-machined Cheebtsam pom tau hais tias:

● 55% lub neej qaug zog ntev dua nyob rau hauv qhov kev ntsuam xyuas pob khawm

● Qhov tseeb qhov tseeb tsis pub dhau ± 0.01mm hla cov khoom siv

2.Kev cuam tshuam nyiaj txiag

● Txo qhov kev lees paub los ntawm 34% rau cov tuam txhab kaw qhov rooj

● 18% qis dua tag nrho cov nqi tsim khoom los ntawm kev txo qis rework thiab seem

Kev sib tham

1.Technical Advantages

● Machined qhov chaw tso cai rau cov geometry nyuaj zoo li cov yam ntxwv los tiv thaiv backdrive hauv qhov rais regulators

● Cov khoom siv zoo ib yam txo cov kev ntxhov siab tawg hauv cov ntawv thov siab

2. Cov kev sib tw ua haujlwm

● Cov nqi ib feem ntau dua li stamping lossis molding

● Xav tau cov kws tshaj lij programmers thiab cov neeg ua haujlwm

3. Kev lag luam Trends

● Kev loj hlob nyob rau hauv me me-batch machining rau customized cov neeg siv khoom

● Ntxiv rau kev siv cov txheej txheem hybrid (xws li, 3D luam ntawv + CNC xov)

Xaus

Precision machining ho txhim khu kev ua tau zoo, kev nyab xeeb, thiab lifespan ntawm cov neeg siv khoom thoob plaws ntau qhov kev lag luam. Thaum cov nqi pib siab dua, cov txiaj ntsig ntev hauv kev ntseeg tau thiab cov neeg siv khoom txaus siab ua pov thawj rau kev nqis peev. Kev saws me nyuam yav tom ntej yuav raug tsav los ntawm:

● Ua kom automation kom txo tau cov nqi machining

● Tighter integration nrog tsim-rau-manufacturing software

Post lub sij hawm: Oct-10-2025