Nyob rau hauv ib puas-evolving ntiaj teb no ntawm manufacturing, tig CNC machining qhov chaw yog ua ib tug kiv puag ncig. Nrog rau kev lag luam xav tau ntau dua precision, efficiency, thiab customization, CNC (Computer Numerical Control) technology tau dhau los ua qhov tseem ceeb, tshwj xeeb tshaj yog hauv kev ua haujlwm. Cov khoom siv ua kom zoo nkauj zoo nkauj no tau siv zog txhua yam los ntawm cov tshuab tsheb mus rau cov khoom siv hauv aerospace, ua rau CNC machining qhov chaw yog lub hauv paus ntawm kev lag luam niaj hnub.

Tab sis vim li cas cov khoom no yog qhov tseem ceeb heev, thiab lawv rov txhais li cas rau kev tsim khoom? Cia peb tshawb nrhiav yuav ua li cas tig CNC machining yog teeb tsa cov qauv tshiab rau kev ua tau zoo, kev ua tau zoo, thiab kev ua haujlwm ntau lawm.

Dab tsi yog CNC Machining Parts?

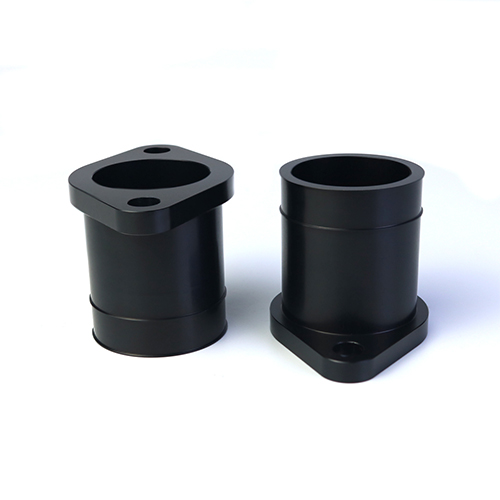

Ntawm nws cov tub ntxhais, tig CNC machining cuam tshuam nrog tshem cov khoom los ntawm kev sib hloov ua haujlwm los tsim cov duab cylindrical meej. Cov txheej txheem no yog ua tiav siv CNC tshuab dhos siab heev, uas yog programmed los tsim cov khoom nrog tshwj xeeb raug thiab sib xws.

Cov piv txwv ntawm tig CNC machining qhov chaw muaj xws li shafts, bushings, spindles, screws, thiab flanges, tag nrho cov uas yuav tsum tau high precision los xyuas kom meej seamless kev ua tau zoo nyob rau hauv lawv cov kev siv.

Tsis zoo li cov txheej txheem tig, CNC tshuab tuaj yeem tsim cov khoom nrog micron-theem kam rau ua, ua rau lawv zoo tagnrho rau kev lag luam uas txawm tias qhov sib txawv me me tuaj yeem cuam tshuam kev ua tau zoo, xws li aerospace, khoom siv kho mob, tsheb, thiab hluav taws xob.

Yog vim li cas tig CNC Machining Parts yog Transformative

1. Tsis sib xws Precision

Precision yog lub cim tseem ceeb ntawm tig CNC machining. Niaj hnub nimno CNC lathes tau nruab nrog cov software txiav-ntug thiab cov cuab yeej uas ua rau cov tuam txhab tsim khoom nrog qhov tseeb tsis txaus ntseeg.

Piv txwv li, aerospace Cheebtsam xws li turbine shafts los yog kev kho mob implants zoo li cov pob txha screws yuav tsum tau zoo meej geometry ua raws li lub hom phiaj. CNC tig ua kom cov khoom no ua tau raws li cov qauv kev ua tau zoo, tshem tawm cov kev pheej hmoo cuam tshuam nrog phau ntawv yuam kev.

2. Kev ua tau zoo ntau lawm

CNC tig tshuab ua haujlwm ntawm kev kub ceev thaum tswj kev sib xws thoob plaws kev tsim khoom loj. Tsis zoo li phau ntawv lathes, uas xav tau kev saib xyuas tib neeg tas li, CNC tshuab dhos tuaj yeem ua haujlwm tau zoo, txo cov sijhawm tsim khoom thiab cov nqi zog.

Rau kev lag luam uas tsim cov khoom loj ntawm cov khoom tig, xws li tsheb lossis kev siv tshuab, CNC tshuab tso cai rau kev tsim khoom sai dua, raug nqi ntau yam tsis muaj kev txi zoo.

3. Txhim kho Customization

Kev hloov pauv ntawm CNC machining tso cai rau cov tuam txhab tsim cov khoom tsim tshwj xeeb raws li cov ntawv thov tshwj xeeb. Nrog cov software siab tshaj CAD/CAM, engineers tuaj yeem tsim cov geometries nyuaj thiab txhais ncaj qha rau hauv CNC program.

Txawm hais tias nws yog ib qho qauv tsim los yog ib pawg ntawm cov khoom siv rau kev ua haujlwm siab, CNC tig muaj kev ywj pheej tsim tsis muaj kev sib piv. Qhov no yog tshwj xeeb tshaj yog muaj nqis nyob rau hauv cov sectors xws li motorsports thiab khoom kim heev, qhov twg tshwj xeeb, high-kev ua tau zoo qhov chaw nyob rau hauv siab thov.

4. Superior Material Compatibility

CNC tig tshuab tuaj yeem ua tau ntau yam khoom siv, los ntawm cov khoom siv hlau xws li txhuas, hlau, thiab tooj dag, mus rau cov alloys siab heev thiab cov khoom sib xyaw xws li titanium thiab carbon fiber.

Qhov kev ua tau zoo no ua rau cov tuam txhab ua kom tau raws li ntau qhov kev xav tau ntawm kev lag luam uas xav tau cov ntaub ntawv nrog cov khoom tshwj xeeb, xws li cov khoom siv dav hlau sib sib zog nqus lossis cov khoom siv kho mob corrosion-resistant.

Daim ntawv thov tsav tsheb xav tau tig CNC Machining Parts

1.Automotive Kev Lag Luam

Tig CNC machining qhov chaw yog qhov tseem ceeb hauv kev lag luam tsheb, tsim cov khoom tseem ceeb xws li lub cav pistons, iav ncej, thiab cov kauj ruam. Lub precision thiab durability ntawm CNC tig qhov chaw ua kom pom kev ua haujlwm ntawm lub tsheb, kev ua haujlwm zoo, thiab kev nyab xeeb.

2.Aerospace Engineering

Hauv aerospace, tsis muaj chaw rau qhov yuam kev. CNC-tig qhov chaw xws li aircraft fasteners, tsaws iav Cheebtsam, thiab turbine shafts yog tsim los raws nraim specifications kom tau raws li nruj xav tau ntawm lub davhlau puag ncig.

3.Cov cuab yeej kho mob

Kev lag luam kev kho mob tso siab rau CNC machining ntau rau kev tsim cov cuab yeej phais, kev cog lus, thiab cov khoom siv prosthetics. Tig CNC machining kom ntseeg tau tias cov khoom no tsis yog tsuas yog meej tab sis kuj biocompatible thiab muaj kev nyab xeeb rau kev siv hauv cov ntawv thov rhiab.

4.Electronics

Los ntawm cov khoom sib txuas me me rau cov dab dej kub, CNC tig ua lub luag haujlwm tseem ceeb hauv kev lag luam hluav taws xob. Kev muaj peev xwm ua haujlwm nrog cov ntaub ntawv me me thiab tsim cov khoom me me, sib txawv tau ua rau CNC tig indispensable nyob rau hauv daim teb no.

Technological Advancements hauv CNC tig

Lub teb ntawm CNC tig yog evolving sai heev, nrog innovation uas txhim khu kev ceev, raug, thiab functionality:

1. Multi-Axis CNC Lathes

Niaj hnub nimno CNC lathes tam sim no muaj peev xwm ua tau ntau lub axis, ua kom cov geometries nyuaj los tsim nyob rau hauv ib qho kev teeb tsa. Qhov no tshem tawm qhov xav tau ntawm kev ua haujlwm thib ob, txo cov sijhawm tsim khoom thiab cov nqi.

2. Kev koom ua ke IoT

Smart CNC tshuab nruab nrog IoT sensors tso cai rau lub sijhawm saib xyuas kev ua haujlwm ntawm machining, ua kom muaj kev tswj xyuas zoo thiab kev saib xyuas zoo.

3. Cov cuab yeej txiav Advanced

Kev txhim kho cov cuab yeej ua haujlwm siab, xws li pob zeb diamond-tipped lossis coated carbide inserts, tau txhim kho kev ua haujlwm zoo thiab siv lub neej ntev, txawm tias ua haujlwm nrog cov ntaub ntawv tawv xws li titanium lossis Inconel.

Lub neej yav tom ntej ntawm tig CNC Machining qhov chaw

Raws li kev lag luam tseem xav tau ntau dua precision thiab efficiency, tig CNC machining yuav ua lub luag haujlwm tseem ceeb zuj zus. Kev sib koom ua ke ntawm kev txawj ntse txawj ntse thiab automation yog npaj los ua CNC tig tshuab txawm ntau ntse thiab muaj peev xwm, tso cai rau kev hloov kho ntau dua thiab nrawm dua.

Ntxiv mus, nrog rau kev thawb mus rau kev ruaj khov, CNC machining yog siv cov kev coj ua hauv eco, xws li txo cov khoom pov tseg los ntawm kev ua kom zoo dua qub thiab siv cov khoom siv rov ua dua tshiab.

Xaus: Tig CNC Machining Parts li Catalyst rau Kev Txhim Kho

Qhov nce ntawm tig CNC machining qhov chaw sawv cev yog ib qho tseem ceeb leap rau pem hauv ntej rau kev lag luam. Los ntawm kev sib txuas cov precision, efficiency, thiab versatility, cov khoom no yog tsav innovation nyob rau hauv ntau yam kev siv, los ntawm kev thauj mus los thiab kev kho mob mus rau technology thiab kev tiv thaiv.

Raws li CNC thev naus laus zis txuas ntxiv mus, qhov ua tau rau tig CNC machining qhov chaw yog qhov tsis muaj kev txwv. Rau cov tuam txhab lag luam xav kom nyob twj ywm kev sib tw hauv lub ntiaj teb hloov pauv sai, kev nqis peev hauv kev txiav CNC tig lub peev xwm tsis yog ib qho kev xaiv - nws yog qhov tsim nyog.

Txawm hais tias nws yog lub zog rau cov tsheb tiam tom ntej, ua kom lub neej txuag kev kho mob, lossis tsim cov khoom siv hluav taws xob hauv lub neej yav tom ntej, tig CNC machining qhov chaw yog nyob rau hauv pem hauv ntej ntawm precision manufacturing nyob rau hauv lub xyoo pua 21st.

Post lub sij hawm: Jan-06-2025