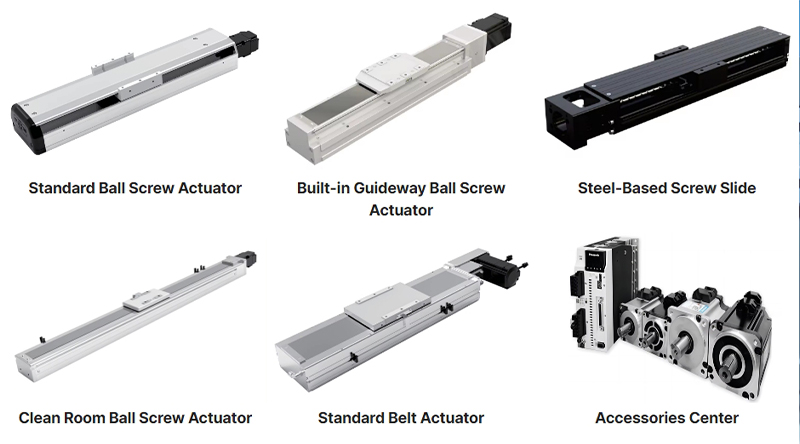

PFTH17 1-axis Pob Screw Drive Kab qhia kev tsheb nqaj hlau sib piv CNC slider module

Nkag mus rau 750W CNC slider module, nruab nrog 1-axis Ball Screw Drive Linear qhia kev tsheb nqaj hlau tshuab. Nrog rau cov kev qhia tshwj xeeb zoo li ntawm 250-2000mm / s ceev, 320-2563N stroke, thiab stroke pitch spanning 50-1250mm, no revolutionary module sawv poised los hloov cov txheej txheem machining. Nyob rau hauv tsab xov xwm no, peb delve rau hauv lub peev xwm ntawm 1-axis Pob Screw Drive Linear qhia kev tsheb nqaj hlau CNC slider module thiab muab piv nrog cov kab lus qhia kab ib txwm siv, qhia txog nws lub peev xwm los hloov kho cov qauv kev lag luam.

Unveiling 1-axis Pob Screw Drive Linear Guide Rail CNC Slider Module

Nyob rau hauv lub plawv ntawm precision machining lus dag lub CNC slider module, ib qho tseem ceeb tivthaiv uas pab kom meej meej txav thiab muab tso rau ntawm lub tshuab cuab yeej. Kev koom ua ke ntawm 1-axis Pob Screw Drive Linear qhia kev tsheb nqaj hlau thev naus laus zis txhawb nqa cov qauv no rau qhov siab tshiab ntawm kev ua haujlwm. Nrog lub zog tso zis ntawm 750W, nws muaj qhov tsis sib xws ntawm qhov nrawm thiab qhov tseeb, ua rau nws zoo tagnrho rau ntau yam kev siv machining.

Key Specifications thiab Performance Metrics

1.Speed Range (250-2000mm / s): Lub peev xwm ua haujlwm nyob rau hauv qhov kev nrawm nrawm no tso cai rau kev pom zoo rau kev sib txawv ntawm machining. Txawm hais tias nws yog traversing ceev los yog zoo tiav, CNC slider module muab kev ua tau zoo ib yam ntawm cov chaw sib txawv.

2.Stroke thiab Stroke Pitch (320-2563N, 50-1250mm): Lub peev xwm ua rau lub cev muaj zog ua rau lub module kom npog ntau yam ntawm cov lus tsa suab, haum rau ntau hom kev ua haujlwm nrog kev yooj yim. Tsis tas li ntawd, qhov kev kho mob stroke pitch txhim kho qhov yooj yim, tso cai rau kev kho kom haum raws li cov kev xav tau tshwj xeeb.

Qhov zoo tshaj li Traditional Linear Guide Rails

1.Enhanced Precision: Kev koom ua ke ntawm Ball Screw Drive thev naus laus zis ua kom lub zog zoo dua thiab meej dua piv rau cov kab lus qhia kev sib tw, uas ua rau kev ua haujlwm zoo tshaj plaws thiab qhov chaw tiav.

2.Higher Speeds: Nrog rau kev muaj peev xwm ua tiav qhov nrawm txog li 2000mm / s, CNC slider module muaj cov khoom lag luam tseem ceeb tau txais txiaj ntsig zoo piv rau cov kab lus qhia kab ib txwm siv, ua kom lub voj voog nrawm dua thiab txo cov sij hawm txhuas.

3.Greater Load Capacity: Lub zog tsim ntawm lub module tso cai rau ntau dua load peev xwm, ua rau nws haum rau machining hnyav-duty workpieces nrog yooj yim thiab stability.

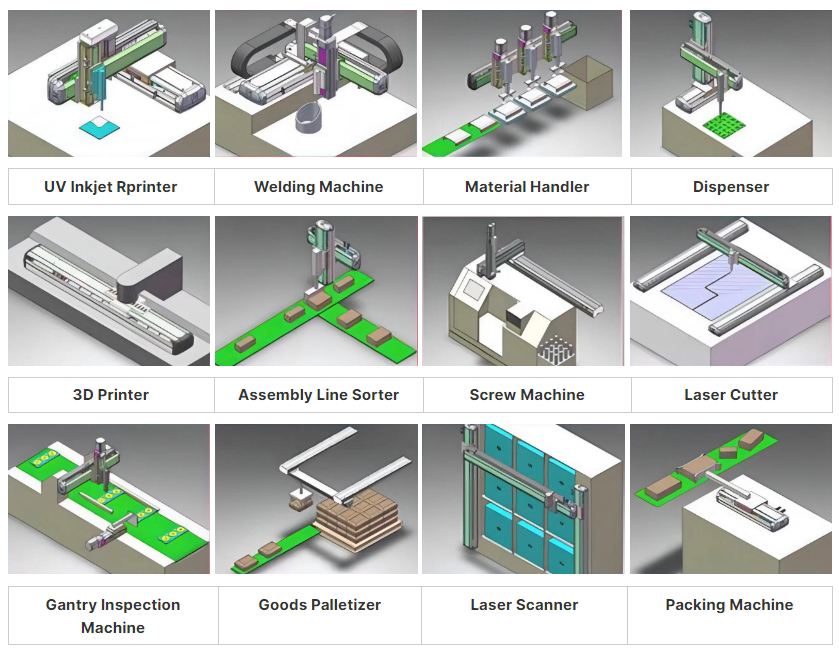

Daim ntawv thov thiab kev lag luam cuam tshuam

versatility thiab kev ua tau zoo ntawm 1-axis Pob Screw Drive Kab qhia kev tsheb nqaj hlau CNC slider module ua rau nws tseem tsis tau muaj nyob hauv ntau qhov kev lag luam, suav nrog tsheb, aerospace, hluav taws xob, thiab kev tsim khoom. Los ntawm precision milling thiab drilling mus rau high-speed machining thiab engraving, nws muaj peev xwm ua rau cov tuam txhab ua tau raws li cov kev xav tau ntawm cov khoom siv niaj hnub no.

Q: Ntev npaum li cas customization siv sijhawm?

A: Customization ntawm linear guideways yuav tsum txiav txim siab qhov loj thiab specifications raws li qhov yuav tsum tau, uas feem ntau yuav siv sij hawm ib ncig ntawm 1-2 lub lis piam rau ntau lawm thiab xa tom qab tso qhov kev txiav txim.

Q. Cov kev ntsuas thiab cov kev cai dab tsi yuav tsum tau muab?

Ar: Peb xav kom cov neeg yuav khoom muab peb qhov ntev ntawm txoj kev taw qhia xws li qhov ntev, qhov dav, thiab qhov siab, nrog rau lub peev xwm thauj khoom thiab lwm yam ntsiab lus los xyuas kom meej qhov kev hloov kho.

Q. Puas tuaj yeem muab cov qauv dawb?

A: Feem ntau, peb tuaj yeem muab cov qauv ntawm tus neeg yuav khoom tus nqi rau tus nqi coj mus kuaj thiab tus nqi thauj khoom, uas yuav tau them rov qab thaum tso qhov kev txiav txim yav tom ntej.

Q. Yuav ua li cas rau ntawm qhov chaw teeb tsa thiab kev debugging?

A: Yog tias tus neeg yuav khoom xav tau ntawm qhov chaw teeb tsa thiab kev debugging, tus nqi ntxiv yuav raug siv, thiab kev npaj yuav tsum tau tham ntawm tus neeg yuav khoom thiab tus muag khoom.

Q. Hais txog tus nqi

A: Peb txiav txim siab tus nqi raws li cov kev xav tau tshwj xeeb thiab cov nqi kho kom haum ntawm qhov kev txiav txim, thov hu rau peb cov neeg siv khoom rau tus nqi tshwj xeeb tom qab lees paub qhov kev txiav txim.